Wire Caps vs. Electrical Tape: Which is the Safer Choice?

You’re in the middle of an electrical project, and the elusive wire caps are nowhere to be found. The electrical tape is right there, tempting you. But is it a safe alternative?

Wire caps, often called wire nuts, are pivotal for electrical safety. They guard against short circuits, insulate exposed wires, ensure consistent connections, and are preferred for permanent setups.

While electrical tape may offer a temporary solution, it lacks the durability, heat resistance, and moisture protection wire caps provide. The clear recommendation is to prioritize using wire caps over electrical tape for long-term electrical safety.

Let’s get into detail below.

The Purpose of Wire Caps

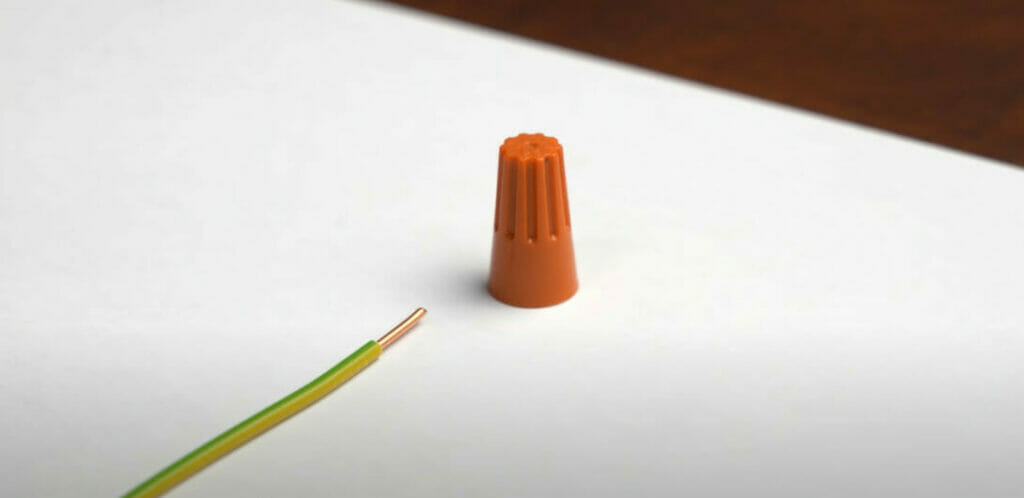

Let’s dive right into the heart of our topic. Wire caps, or as some may know, wire nuts, are crucial in electrical installations. They’re not just there for show; they have an important job.

- Safety First: To secure bare wire ends and keep them from causing a potential short circuit or – worse yet – sparking up an electrical fire.

- Preventing Accidents: It safely houses these exposed ends and insulates them from external elements that could trigger hazardous scenarios.

- Consistent Connections: Wire caps also lend themselves well to maintaining solid and consistent connections between your wires.

- Durability & Simplicity: Durability and ease of use make wire caps popular among DIY enthusiasts and professional electricians.

Electrical Tape vs. Wire Caps: A Quick Comparison

Now, let’s dive into the real question: Should you use electrical tape instead of wire nuts? The short answer is it’s not recommended. But why is that?

In this quick comparison, we’ll shed light on the strengths and weaknesses of each, guiding you to make informed decisions for your next electrical project.

| Criteria | Wire Caps (Wire Nuts) | Electrical Tape |

|---|---|---|

| Design & Purpose | Plastic and metal pieces are designed to twist onto wire ends, preventing unintended contact. | Used mainly for insulation and minor repairs. |

| Ease of Installation | Simple twist-on application. | Requires skill to ensure proper connection and insulation. |

| Insulation & Security | Provides excellent insulation and reduced chances of loose connections. | They are used mainly for insulation and minor repairs. |

| NEC Guidelines | Approved and recommended by the National Electric Code (NEC). | It can unravel over time, offering less protection compared to wire caps. |

Why Safety Experts Prefer Wire Caps Over Electrical Tape

I’ll be straightforward: there are serious safety considerations to remember when using electrical tape instead of wire caps.

- Heat Issues: Electrical connections can get hot, especially if carrying a lot of current. Here’s the catch: Most electrical tapes aren’t designed to handle high temperatures.

- Moisture Threat: Water has a knack for getting into places it shouldn’t be; unfortunately, electrical tape doesn’t offer much resistance against it.

- Durability Concerns: Electrical tape can age and degrade over time, exposing bare wires, which can cause arcing or short-circuiting.

Quick Facts:

- The U.S. Consumer Product Safety Commission reports an annual average of 50 deaths and more than 2,000 injuries from home electrical failures.

- According to the National Fire Protection Association (NFPA), approximately half of all home structure fires involving electrical distribution equipment were caused by issues like these.

Wire Caps: A Clear Winner

When we’re knee-deep in a DIY electrical project, it’s easy to reach for the nearest roll of electrical tape. Yet, there are certain times when wire nuts or caps truly shine.

This section delves into the specific scenarios where wire caps shine, their key strengths, and why they are preferred for permanent connections.

| Wire Caps Strengths | Description |

|---|---|

| Secure Grip | Ensure wires remain firmly connected. |

| Weather Resistance | Suitable for outdoor wiring exposed to the elements. |

| Superior Insulation | Reduces electric shock and fire risks. |

| Convenient Inspection | Easy access for inspection and maintenance. |

Electrical Tape: A Temporary Fix

Let’s face it, we’ve all been there. You’re knee-deep in a DIY project and realize you’re fresh out of wire caps. It’s late, the stores are closed, and your eagerness to finish is high. The easy solution? Reach for that roll of electrical tape sitting in your toolbox.

While it may seem like a quick fix, using electrical tape instead of wire caps is not recommended for long-term use. Why? Well, let’s break it down.

| Limitations of Electrical Tape | Description |

|---|---|

| Adhesive Weakens | Electrical tape is less durable, exposing your wires to air and potential damage. |

| Less Durable | Electrical tape is less durable, leaving your wires exposed to air and potential damage. |

| Inferior Resistance | It offers lower heat, water resistance, and insulation. |

Acceptable Scenarios for Electrical Tape

I’ve got to tell you that sometimes using electrical tape instead of wire caps might seem the right choice.

Let’s say you’re in a pinch, and no wire nuts are handy. In these instances, reaching for that roll of electrical tape could be tempting.

The table below outlines these scenarios:

| Scenario | Description |

|---|---|

| Low Voltage | Suppose you’re working on an older home where knob-and-tube wiring is still in use. If all else fails and no modern alternatives are available immediately, using tape could be considered acceptable here, too. |

| Older Homes | Suppose you’re working on an older home where knob-and-tube wiring is still in use. If all else fails and no modern alternatives are available immediately, using tape could be considered acceptable here, too. |

| Temporary Repairs | For a quick, temporary fix when a wire is accidentally cut or nicked during installation or repair. |

| Labeling and Identification | Using colored electrical tape to mark wires for identification. |

| Reinforcement | Electrical tape might be used for temporary connections when testing or prototyping circuits. |

| Prototype Circuitry | When testing or prototyping circuits, Electrical tape might be used for temporary connections when testing or prototyping circuits. |

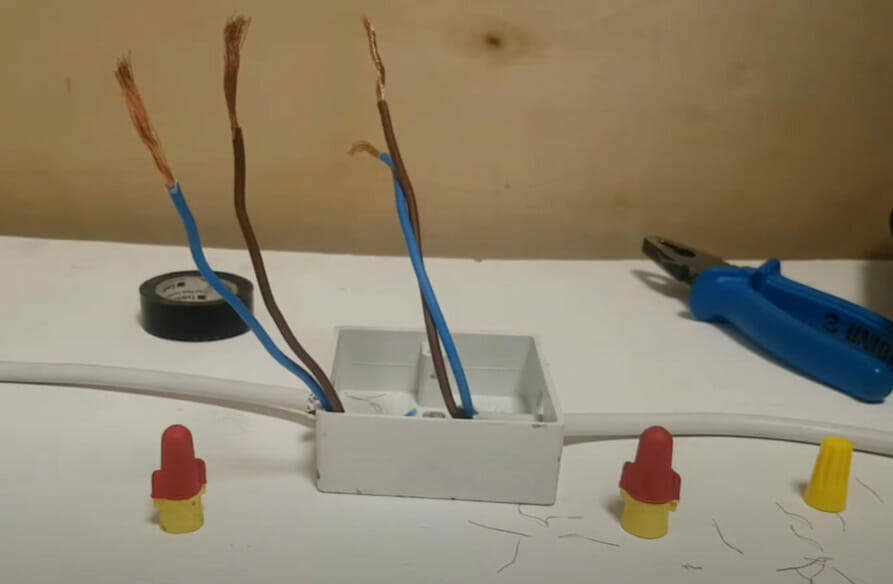

Wire Caps: Best Practices

Let’s dive into the best practices when using wire caps, or as some call them, wire nuts. They’re more than just a preference – they’re essential for safe electrical work.

| Best Practice | Description & Recommendations |

|---|---|

| Choose the right size | – Wire caps come in various sizes to accommodate different gauges of wires. It’s not a one-size-fits-all situation. – If you’re dealing with 12-gauge wires, don’t try to force them into a cap meant for 16-gauge wires. That’s asking for trouble. |

| -It’s worth investing in something that’ll last longer and provide better protection is worth. | -It’s worth investing in something that’ll last longer and provide better protection is worth. |

| Twisting Technique | – Pre-twist stripped wire ends together with pliers. – Always twist in a clockwise direction. |

| Secure and Inspect | – Conduct a tug test post-application. – Always make sure your cap has been tightened properly! |

| Avoid Overloading | – Do not exceed the recommended wire limit for a cap. – Avoid cramming in extra wires. |

| Limit Temporary Use | – Wire caps are generally for permanent connections. – If used temporarily, seek a more permanent solution soon. |

| Environmental Considerations | – Consider temperature and moisture ratings for caps. – Ensure caps are suited for the working environment. |

| Regular Maintenance and Inspection | – Conduct periodic inspections of all connections. – Check for signs of wear, corrosion, or damage and replace if necessary. |

Now, let’s talk about how you put these things on. Here are the steps:

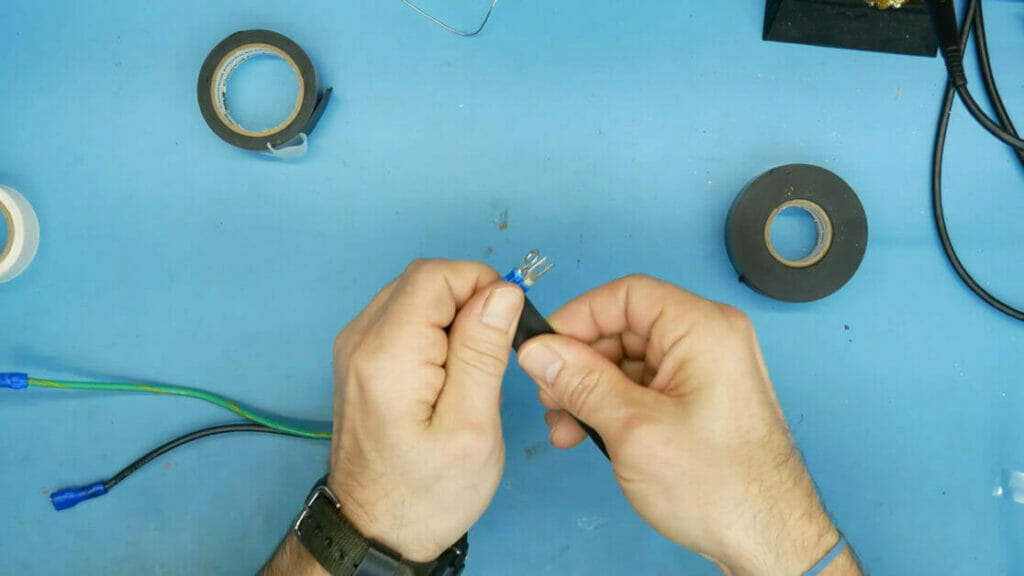

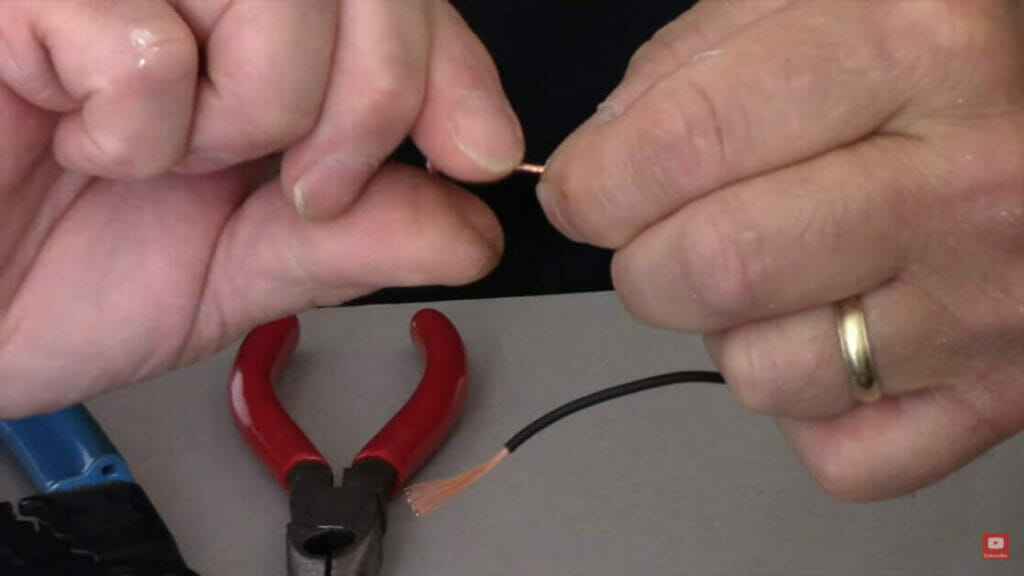

Step 1: Strip Wires

- You’ll need about half an inch of exposed copper wire.

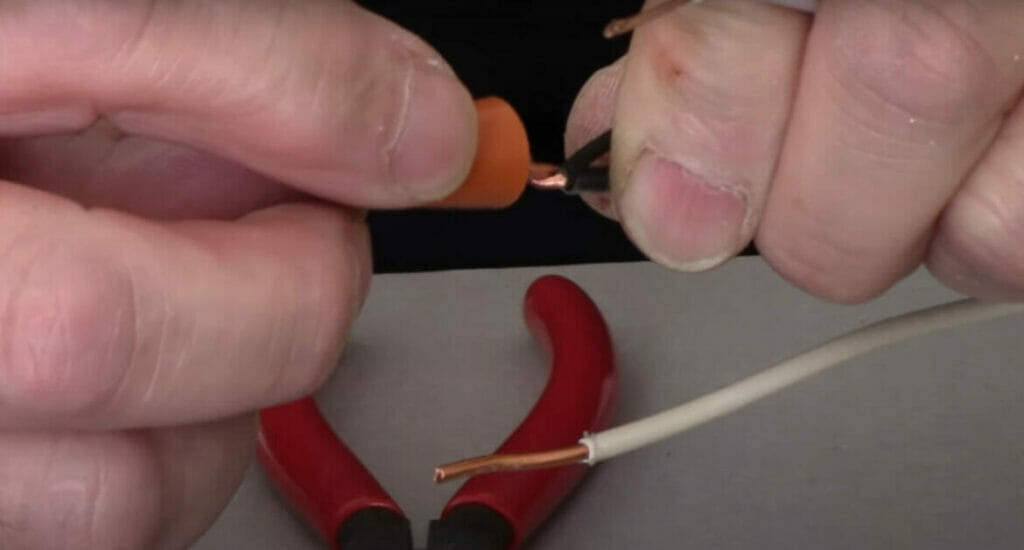

Step 2: Line up your stripped ends

- All those copper tips should be even with each other.

Step 3: Twist Together

- Twist the wires together firmly in a clockwise direction.

Step 4: Apply the Cap

- Screw it onto the twisted bundle of wires until it feels snug.

Guidelines for Choosing the Right Wire Cap Size

Choosing the correct wire cap size is essential for a safe and secure electrical connection. Follow these guidelines to determine the appropriate size:

- Identify Wire Gauge: Determine the gauge (thickness) of the wires you connect. Wire gauges are typically labeled on the insulation or can be measured using a wire gauge tool.

- Refer to Manufacturer Recommendations: Check the manufacturer’s instructions on the wire cap packaging or product specifications. They often provide guidance on which cap size matches which wire gauge.

- Use a Wire Cap Size Chart: You can find online or printed wire cap size charts that match wire gauges to the recommended cap sizes. These charts simplify the selection process.

- Consider Application: Consider the application and the number of wires you need to connect. In cases where you are joining multiple wires, choose a wire cap that can accommodate them all comfortably.

- Err on the Side of Caution: If uncertain, it’s better to choose a slightly larger wire cap than a smaller one. A larger cap can accommodate various wire sizes and ensure a secure connection.

Common Mistakes to Avoid with Wire Caps

Before you embark on your next DIY electrical project, it’s crucial to understand how to use wire caps correctly and be aware of the common mistakes that can lead to electrical hazards.

- Choosing the Wrong Size: One of the most common errors is selecting wire caps that are either too small or too large for the wire gauge you’re working with. Using the correct size is crucial for a secure connection.

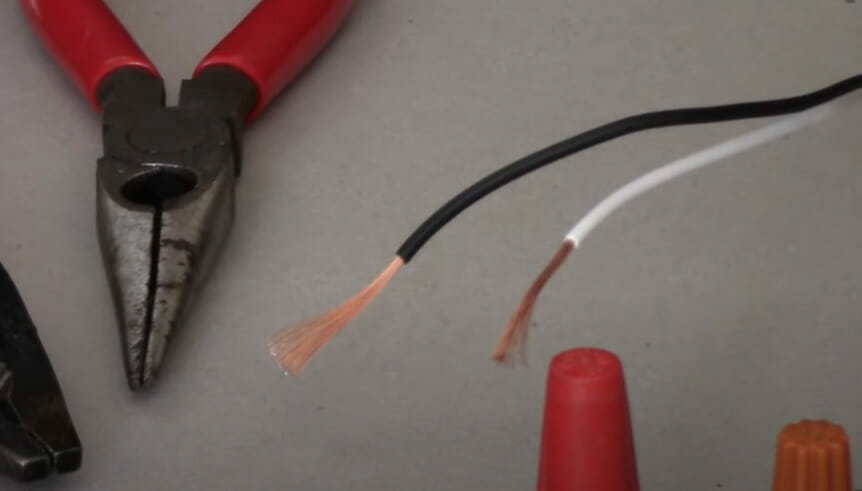

- Inadequate Stripping: Lipping the wire ends properly can lead to poor connections. Ensure you strip the wires to the recommended length, typically about half an inch, exposing enough copper for a reliable connection.

- Insufficient Twisting: A loose twist can result in unreliable connections when joining wires. Make sure to twist the wires together firmly in a clockwise direction to create a snug connection.

- Under-Tightening: Not adequately tightening the wire cap can cause wires to lose over time. After twisting the cap onto the wires, ensure it is securely fastened to prevent potential hazards.

- Mixing Wire Materials: Avoid connecting different wires, such as aluminum and copper, without proper connectors designed for the purpose. Mixing wire materials can lead to corrosion and unreliable connections.

- Not Checking Connections: After installation, inspecting wire cap connections is essential to ensure they are secure and properly insulated. Neglecting this step can lead to hidden issues.

Safety Tips for DIY Electrical Work

Safety should always come first when dealing with electricity. Whether you’re a seasoned DIY enthusiast or a beginner, following strict safety guidelines to protect yourself and your home is essential.

- Turn Off the Power: Always turn off the power supply to the circuit you’re working on before starting any electrical work. Use a voltage tester to confirm that the circuit is de-energized.

- Wear Safety Gear: Invest in appropriate safety gear, including safety glasses, insulated gloves, and clothing, to protect yourself from potential electrical hazards.

- Work in a Well-Ventilated Area: Adequate ventilation is essential when working on electrical projects to prevent the buildup of fumes and ensure a safe working environment.

- Use the Right Tools: Ensure you have the correct tools for the job and that they are in good condition. Using damaged or inappropriate tools can increase the risk of accidents.

- Read Manuals and Guidelines: Familiarize yourself with the manufacturer’s instructions, guidelines, and local electrical codes relevant to your project. Compliance with safety standards is critical.

- Seek Professional Help When Needed: If you’re unsure about any aspect of your electrical project or if it involves complex wiring, don’t hesitate to consult a qualified electrician. Safety should always be the top priority.

Frequently Asked Questions

Q1: Can I use wire caps on aluminum wires?

A1: Yes, wire caps designed for aluminum wiring are available. These specialized caps for aluminum wires are crucial to prevent corrosion and ensure safety.

Q2: Can I reuse wire caps?

A2: It’s generally not recommended to reuse wire caps once they’ve been installed. Wire caps can deform or lose their effectiveness after use. It’s safer to use new caps for each connection.

Q3: Can I use wire caps for outdoor electrical connections?

A3: Yes, wire caps designed for outdoor use are available. These caps are weather-resistant and protect outdoor electrical connections from the elements.

Q4: Are wire caps safe for high-temperature environments?

A4: Wire caps are designed to withstand standard temperature ranges. For high-temperature applications, consider using heat-resistant connectors or consult a professional electrician.

Q5: How can I tell if a wire cap is securely fastened?

A5: After twisting the cap onto the wires, gently tug it to ensure it’s securely fastened. A properly secured cap should not easily come off.

Q6: Can I use wire caps for connecting wires of different gauges?

A6: It’s best to avoid connecting wires of significantly different gauges using wire caps, as it can lead to unreliable connections. Instead, use appropriate connectors designed for such scenarios.

References

Website Resources:

- Electrical Safety Foundation International (ESFI) – https://www.esfi.org/

- This Old House – https://www.thisoldhouse.com/

- Family Handyman – https://www.familyhandyman.com/

Video Resources:

Right On with Jon Crane

Everyday Home Repairs

Get It Done Home Repair

The Shop

Everyday Home Repairs

MIX-BLOG TV

GreatScott!