How to Test a Furnace Pressure Switch with a Multimeter

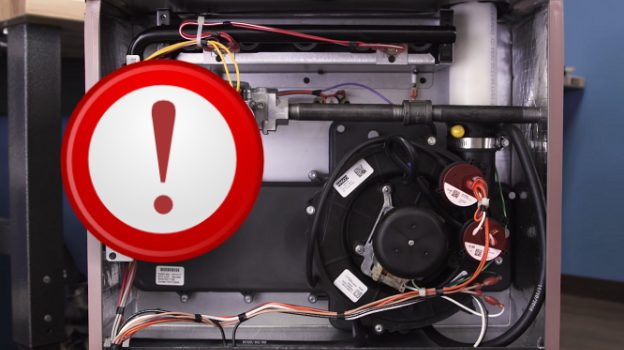

Pressure switches are critical to a system’s operations. They validate that gas is being vented from a furnace before starting it, and it sends a signal to the furnace control board to verify that the inducer motor is operating. However, a furnace pressure switch may also fail or become trapped in the open position which may have underlying issues that would be best diagnosed through testing.

In general, to test a furnace pressure switch with a multimeter, pull the wire connectors of the switch wires and pressure switch. Set the multimeter to the continuity or Ohms setting. Using multimeter leads, touch one on each switch terminal then read the charges. If the switch closes, then it’s operational.

So, in this guide, let me show you more about how to test a furnace pressure switch with a multimeter.

6 Steps to Test a Furnace Pressure Switch

Step 1: Disconnect the switch wires. Pull the wires off the switch terminals to disconnect the wires linked to the pressure switch. (1)

Step 2: Set the multimeter to the continuity or Ohms setting (typically indicated by a Ω symbol). Ensure that you’re monitoring single ohms rather than mega-ohms.

Step 3: Turn the pressure switch around. You’ll see different terminals. Get your multimeter leads and touch one on each switch terminal in those terminals.

Step 4: The furnace will then be turned on.

Step 5: Then, the draft inducer motor will activate and start blowing air out the vent, creating a vacuum that draws the diaphragm in and closes the switch.

Step 6: With your multimeter, check for any changes and whether or not the switch closes.

If the multimeter’s reading is 0 or close to 0, then you are testing a closed switch indicating that it’s functioning well and exhibits continuity. However, if you see infinity or a higher multimeter reading, the switch remains open, meaning there’s no change in continuity, and it’s a bad pressure switch. Hence, you must replace the switch right away to solve the problem.

Other Possibilities to Note

Before you decide on changing an inducer motor or the switch, you must first take into consideration the other possibilities of the problem, which include:

- A kink in the hose

- The pipe is clogged

- Anything else that prevents the inducer motor from releasing the air from the vent

These factors can make it difficult for your gas furnace pressure switch to function correctly. Thus, before you eventually decide to change the pressure switch, make sure you look at these issues.

If none of these are present and you’ve exhausted all other options for eliminating reasons and checking for defects, it’s time to replace the pressure switch.

FAQs

What does a pressure switch do?

Furnace pressure switches are safety devices found near a gas forced-air furnace’s draft inducer motor. Its function is to keep the furnace from starting unless the proper venting air pressure is present. It’s made to detect the negative pressure formed by the draft inducer motor during furnace startup and turn off the furnace if the air pressure isn’t sufficient to remove the exhaust gases.

Moreover, a diaphragm is attached to the switch. The diaphragm is then attached to a switch that indicates whether it is open or closed. With the vacuum’s presence, the diaphragm extends and closes the switch. However, the switch remains open if there is no vacuum. In this instance, the furnace is turned off. (2)

What causes the failure of the pressure switch?

1. The draft inducer motor has stopped working.

2. The Intake and combustion air vent is restricted

3. Assembly leaks

4. Condensate drainage is clogged

5. The pressure switch has electrical failure such as loosely connected wires

6. The suction tube is low

7. There’s a blockage in the chimney

What can I do if the furnace pressure switch fails?

If there’s a switch failure, there are several options for recovery:

1. If the pressure switch stops working, you won’t be able to hear the valve opening. If there’s a sound, your pressure switch is in good condition.

2. Turning off the furnace is also an option. Then, check whether the inducer fan is making any noises. Also, if the motor is slow or you notice something else, the motor is the problem and should be replaced, not the switch.

3. Make sure the switch hose is securely fastened. A loose switch hose can be tightened to resolve the issue, but a hole in the line may require sealing. The broken section can alternatively be taken out and the hose reconnected. Make sure the housing is excellent before you begin any of the replacements. After the hose has been repaired, the switch will eventually work correctly.

If you find out that none of these issues exist, you may have a bad pressure switch. To clarify if that’s the problem, you need a multimeter for the testing process.

Take a look at some of our related articles below.

- How to test power window switch with multimeter

- How to test a light switch with a multimeter

- How to test a capacitor with a multimeter

References

(1) pressure – https://www.britannica.com/science/pressure

(2) diaphragm – https://www.healthline.com/human-body-maps/diaphragm

Video Reference