How to Test a Single-Phase Motor with a Multimeter (7 Tests)

This article shows you how to test a single-phase motor using a multimeter.

Single-phase motors are a type of motor that is primarily utilized in homes, stores, offices, and small non-industrial businesses. Although they are simple devices, they can unexpectedly malfunction for various reasons, like any other electrical component. Common problems are running slowly, overheating, and failing to start. A multimeter is a useful electrical diagnostic tool that we can use to figure out the actual cause.

I’ll show you how to conduct 7 different types of tests: general inspection, earth continuity and resistance, power supply, winding resistance, insulation resistance, running amperage, and capacitor discharge. They all require using a multimeter, except the first.

We’ll also talk about single-phase motors and how to test them using a digital multimeter.

Single-Phase Motor Tests

We can run any of the following tests and will go into more detail on them, but here’s a summary of tests:

- General inspection – Do this to get familiar with your motor’s specifications.

- Test earth continuity and resistance to ensure proper grounding and no leakage current.

- Test the power supply – Do this if it’s running slowly or not at all.

- Test the AC motor winding resistance – Do this to check whether the winding is causing a malfunction.

- Test the insulation resistance – Do this if you suspect a short circuit.

- Test the running amperage to check if the motor is drawing the right current (neither too high nor too low).

- Test the capacitor – Do this if you suspect the capacitor is faulty.

Precautions

Some of these tests require the motor to be OFF, but some require it to be ON.

You can unplug the motor from the outlet for tests requiring the motor to be off. For those that require it to be on, take extra precautions when touching the motor.

AC electricity is high voltage. Wear safety gloves while working with the AC electric motor. Also, don’t let water get inside.

Testing a Single-Phase Motor

The main goal of any AC motor test is to gauge the motor’s condition or fix a problem.

The tests are fairly simple if you follow the steps outlined below. Remember to take the necessary precautions first, as you’ll be dealing with AC electricity.

Test 1: General Inspection

A general inspection is the simplest test, and it doesn’t require a multimeter.

As you gain experience handling and working with motors, you will learn quickly what feels right and what it isn’t. You should inspect the following in particular for a single-phase motor:

- General Appearance – Examine the motor’s appearance. Check the body, cooling fan, or shaft for visible burns or damage.

- Motor Shaft – Rotate the motor shaft manually to check the bearing’s condition. If shaft rotation is free and smooth, the bearing is likely in good shape; otherwise, it should be replaced.

The motor nameplate gives valuable information that can aid in determining the motor’s health, i.e., how it is expected to perform. So, take a good look at the nameplate, especially the following electrical information:

- The electric motor type or phase will tell you whether the motor is for single or three-phase power.

- The input frequency is usually 50- or 60Hz and should match your supply.

- The rated current (FLA) is the full load current drawn at the rated voltage.

- The electric motor code (A-V) specifies the locked rotor KVA per horsepower. The closer to V, the higher the incoming current per horsepower.

- The power factor (PF) is the ratio of active power to apparent power (normally stated as a %). It varies with load.

- The capacitor correction indicates the capacitor value in kilovars.

Test 2: Testing Earth Continuity and Resistance

We test for earth continuity and resistance by measuring the resistance of the motor’s casing (body) and earth with a multimeter.

Turn the power to the motor OFF. Set the multimeter to read resistance. Insert the black test lead into the COM port and the red lead into the jack marked Ω. Connect the two probes across different parts of the motor’s casing.

A good motor’s resistance value should not exceed 0.5 ohms. A resistance reading higher than 0.5 ohms indicates a defective motor.

Test 3: Testing the Power Supply

Always check to see if the motor is receiving an acceptable voltage supply, especially if it’s running slowly or not at all.

This test requires extra care because the motor must be receiving power.

Turn the power to the motor ON. Set the multimeter to read AC volts. Insert the black test lead into the COM port and the red test lead into the V jack. Connect the two probes across the load in PARALLEL, which is the circuit ground for the negative (black) probe and a positive spot for the positive (red) probe.

A single-phase motor’s normal voltage levels are roughly 104-128V in a 110-120V system (208-230V in a 220-240V system).

Test 4: Testing the AC Motor Winding Resistance

This test is to measure the motor winding resistance (in ohms).

Since a single-phase motor has three terminals (S, C, and R), you should measure the winding resistance of the following: C to S, C to R, and S to R. The measured value of S to R should be equal to C to S + C to R, i.e.:

S-R value = C-S value + C-R value

The following applies in general to single-phase motors:

- S to R – the reading should be the highest resistance reading.

- C to R – the reading should be the lowest resistance reading.

- C to S – the reading should be in the middle of the values of S-to-R and C-to-R.

Any discrepancy indicates that the electric motor is either defective or needs repair.

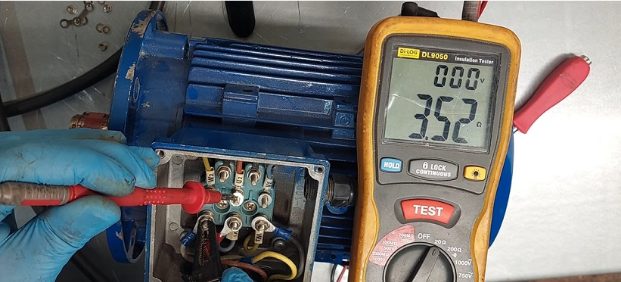

Test 5: Testing the Insulation Resistance

A key symptom of a malfunctioning motor is the failure of insulation resistance.

Insulation resistance is often measured using a megohmmeter or an insulation tester between the motor winding and the ground. Set your insulation resistance tester to 500V and inspect the motor winding’s connection to the earth.

Then, check the phases C-to-E, S-to-E, and R-to-E.

For an electric motor in good condition, the minimum test value should be approximately 1 MΩ.

Test 6: Testing the Running Amperage

Test the full load amps (FLA) with your multimeter or, ideally, a clamp-on meter while the motor is running.

This test requires extra care because the motor must be receiving power, but turn it off initially.

Turn the power to the motor OFF initially. Set the multimeter to read AC current. Insert the black test lead into the COM port and the red test lead into the + jack. Connect the two probes across the load in SERIES so that the current flows through the meter. Now, turn the power ON and take a reading.

Compare the reading to the FLA stated on the motor’s nameplate. A wide deviation from the rated FLA may indicate an issue with the tested motor.

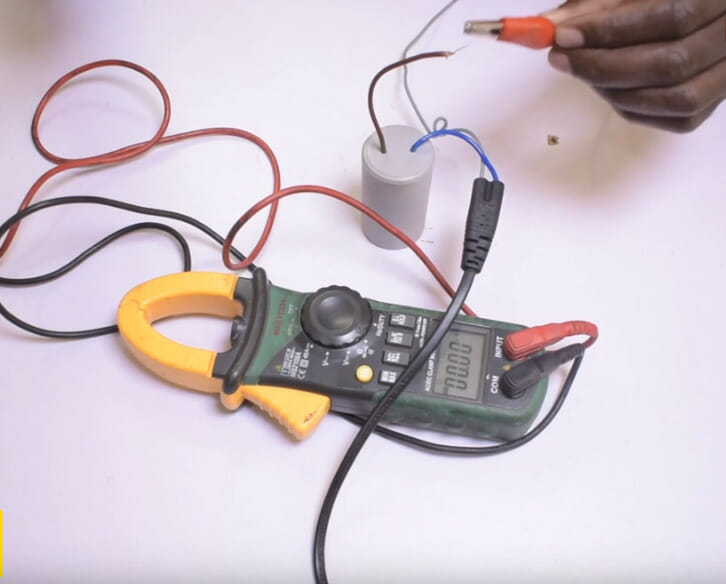

Test 7: Testing the Capacitor

Take extra care because there is a risk of getting an electric shock when handling a capacitor. Only short the capacitor’s terminals momentarily (a second or two) to notice if it discharges.

Set the multimeter to read in the high ohms range. Touch its probes to the corresponding pins on the capacitor (red to positive and black to negative).

The reading should start at zero and move slowly toward infinity.

You can also connect the capacitor across the AC supply to charge it. Then, discharge it by shorting the capacitor’s terminals (as shown above).

If the capacitor discharges, then it’s capable of storing charge and is, therefore, in good condition.

More About Single-Phase Motors

Single-phase motors are typically small motors with low torque.

They cannot produce a rotating magnetic field but produce a pulsating field instead, which requires a capacitor while starting. Otherwise, they are the same as motors generally, which are rotating machines powered by electricity that convert electrical energy into mechanical energy.

Single-phase motors are commonly utilized in small, low-horsepower equipment and machines, such as refrigerators, pumps, compressors, fans, and portable drills. While single-phase motors are mechanically simple, they are not faultless. Due to certain factors, they could run slowly, overheat, or even fail to start on rare occasions.

Hence, it’s crucial to test them regularly to check their condition or the cause of failure.

FAQs

What are the benefits of a single-phase motor?

Single-phase motors provide numerous advantages.

Single-phase motors are less expensive to produce than most other motor types. They are often low-maintenance, require few repairs, and are relatively simple to repair. Also, they will last for years. Most single-phase motor failures are due to an improper application rather than a problem in manufacturing the motor itself.

What are the most prevalent reasons for single-phase motor failure?

There could be various explanations for a single-phase motor failing to start, becoming hot, tripping its overcurrent device, or running intermittently.

The primary issue may be found in the power supply, such as the motor controller or branch circuit wire. Other causes could be a driven load jamming or in its thermal switch, centrifugal switch, or capacitor. Also, a burned wire or winding failure, such as a deteriorated bearing or insulation degeneration, could cause issues. They are usually replaced if the motor is more than ten years old and has less than one horsepower.

Why is testing an electric motor so important?

Because electrical defects are frequently the primary cause of motor failure, it’s critical to figure out how to fix this issue.

You could use various electrical diagnostic equipment, such as a multimeter, to test your single-phase motor. It will assist you in determining the root cause of the problem with your motor. It makes it simple to identify and resolve issues that lead to electrical motor failure. When you find an issue with your electrical motor, you will be able to save money and time by preventing unexpected shutdowns.

References

Brittanica. Horsepower. https://www.britannica.com/science/horsepower

Electric motor nameplate. https://www.linquip.com/blog/single-phase-induction-motor/

Video References

Elektrotechnik in 5 Minuten by Alexander Stöger

Maintenance Engineering Insider

Electreca

Pizzey Technology

KS TiPs