How to Scrap Electric Motors

Working as an engineer for a number of years, I have scrapped a few electric motors and will show you below a few tips on how to scrap them.

You can find electric motors in many devices (i.e., air conditioners). Scrapping them is a great way to recycle and gain some profit. The copper part of the motor is essential for creating highly conductive wires; thus, selling them to scrap yards might be worth your while.

How to Scrap Electric Motors by Hand

- Disassemble the device

- Pull out the electric motor

- Cut one side of the metallic winding

- Pull out the rest of the metallic winding

**Or you can use an Electric Motor Recycling Machine.

Below I’ll go into more detail.

Getting Started

Before starting the scrapping, you need to remember a few details.

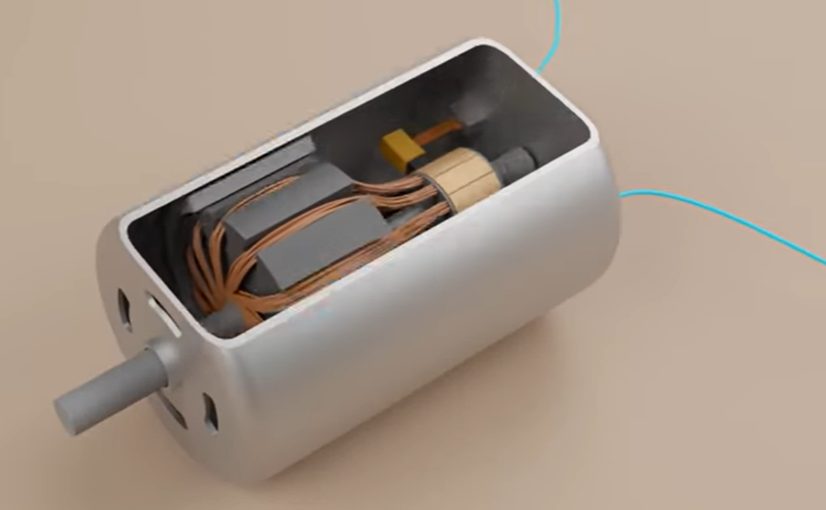

An electric motor consists of:

- A silicon-steel case

- A copper, aluminium or steel coil (winding)

- Extra insulated copper wires connect the motor to the rest of the device

You can scrap an electric motor with two methods:

- By hand

- With a machine

Both methods are efficient, and you can use them for recycling electric motors. However, it is important to clarify that you can not recycle all motor scraps.

You can only recycle copper wires.

How to Test If Your Motor Has Copper Wires

You will need a diamond file.

After you have pulled the motor out of the device, scratch the wires with the diamond file. I will explain how to pull a motor out of a device later in the article.

If the colour under the scratched area is silver, then you are dealing with a motor with a steel or aluminium coil.

If the colour is somewhat red, you are dealing with copper winding.

The second coil is the one that you can use for recycling.

Scrapping Your Electric Motor by Hand

When scrapping an electric motor by hand, you need a few extra tools:

- Screwdriver

- Drill (optional)

- A blade grinder (optional)

- Wire cutter

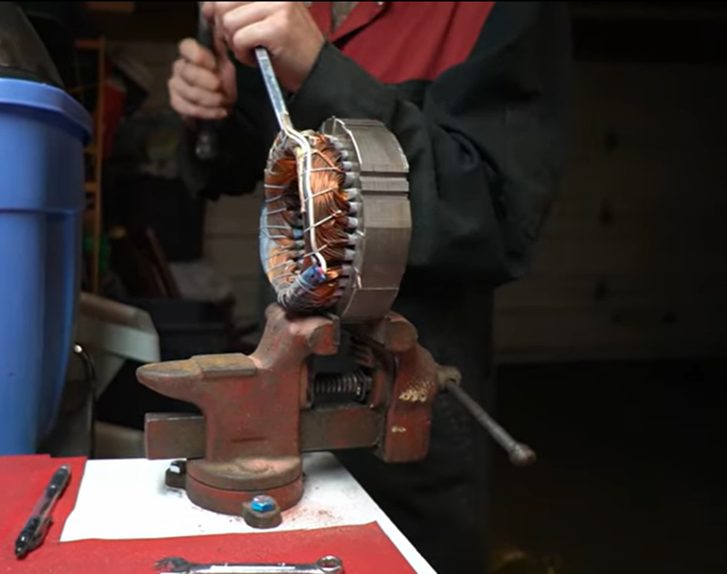

- Large Vice

- Large metallic rod

- Hammer

- Protective goggles

You need to leave the motor unused for at least one hour to prevent any accidents.

Step 1: Disassembling the Device

Let’s say that you haven’t yet taken the motor out of your device.

Each device has a plastic or steel shell wrapped around the electrical mechanism to protect it.

Remove the screws on the shell by using a drill or screwdriver.

Step 2: Check for Additional Screws

Once you detach the motor from the shell, check if the motor is stabilised further inside the plastic or steel cover with more screws.

If so, with the screwdriver, take off the screws.

Step 3: Release the Motor from the Electrical Mechanism

You now need to check the electrical mechanism.

Most motors connect to additional insulated copper wires. These wires help connect the rest of the device to the energy source. If you find such wires cut them off with the wire cutter.

Pull the motor out of the device and place it on the vice so you can begin the scrapping process.

You need to secure the motor on the clamp as much as possible, as you will apply a lot of force to the engine.

Step 4: Cutting Out the Metallic Winding

Now, you will cut the coil into pieces, by using one of the following two methods:

- With the wire cutter, crop one side of the metal winding into pieces.

- With the blade grinder, remove one side of the coil entirely.

Step 5: Pulling Out the Coil

Using the metallic rod and the hammer, strike the coil repetitively. Thus, the copper can exit from the other side of the motor.

You will be left with pieces of scrap metal and a silicon-steel case.

Scrapping Your Electric Motor with a Machine

The specialised device you will be using is called an Electric Motor Recycling Machine.

It consists of two smaller machines:

- Wire Cutting

- Wire Pulling

As well as some integrated tools:

- Wire cutter

- Lifting platform

- Batter boards

- Switch buttons

- Pinchers

Each compound follows the same method as you would by hand.

How to Operate

After you have pulled the motor out of the device, you may use the machine.

- Place the electric motor on the first compound of the machine. It will cut one side of the metallic winding.

- Place the electric motor on the lifting platform.

- With the switch button, lift the platform to the batter board’s height.

- The pinchers of the machine’s Wire Pulling part will remove the coil from the case.

Similarly to the first method, you will be left with the scrap metals and the case.

Wrapping Up

Recycling electric motors is a great way to protect the environment and gain some gain additional profit.

You can opt to sell your leftover metals to scrap yards or send them to scrap metal recycling stations. Remember, only copper windings can be recycled, not aluminium or steel coils.

You can either see fit to remove the coil from the case by hand or with a machine.

Take a look at some of our related articles below.

- Where to find thick copper wire for scrap

- How to protect electrical wires from rats

- What happens if ground wire is not connected

Video References

Jared Owen

thubprint

TestDriven

Scrap Farm

E-waste Recycling Machinery