How to Protect Spark Plug Wires from Headers (Tips)

By the end of this article, you’ll be able to protect your spark plug wires from the header.

As a car owner, you may have felt anger when you see your automobile’s spark plug wire smoking from the engine’s header. It’s a bad situation and hiring experts to fix it is very costly. Learning the skills to protect spark plugs will help you mitigate the problem and lessen your expenses.

In general, you can protect spark plug wires from headers through these steps:

- Insulation Boots

- Heat Shield

- Electric Tape with plastic cover

- Boot Sleeves

- Fiberglass socks

We’ll go through the details below.

Reasons Why Spark Plug Wires Burn From Headers

To resolve the issue, we must first understand why spark plug wires ignite or melt from motor headers.

Engine headers are an accessory component allowing the engine to quickly release exhaust gasses from the cylinder. Because the released gas is hot, the engine header heats up in cycles.

The spark plug and associated connections are located right next to the header. It is nearly always close to the spark plug wires. It usually transmits heat to the spark plug wire when it warms up. This is how they burn or melt when in touch for an extended period.

The Effect of Spark Plug Wires Burning and Melting

As you may know, the spark plug is in charge of starting the engine and establishing the first spark.

If its wiring is compromised, the ignition process is disrupted. Because the engine’s combustion chamber lacks electric sparks, it burns less gasoline, lowering its efficiency.

How to Protect Spark Plug Wires from Headers

The last thing you want is for your spark plug wire to be damaged by the header.

If you have the money, purchasing spark plug wire heat shields, boot guards, or boot sleeves is the best option. There are other low-cost alternatives, such as taping plastic caps or utilizing zip ties.

1. Insulation Boots

Insulation boots are spherical and are installed between the spark plug wires’ cylinder heads. They are affordable yet effective, as they can withstand temperatures as high as 650 °C (1200 °F).

They reflect heat, preventing it from contacting your spark plug wires, and are made of thermal-barrier materials.

They are developed with superior heat shield technology, one of the most excellent methods to safeguard spark plug wires.

2. Heat Shields

These work the same way as insulative boot protection but are composed of different materials. They have ceramic insulation and stainless steel components.

They easily reflect heat, forming a heat-protective barrier that may protect your spark plug wires from temperatures up to 980 degrees Celsius.

3. Electric Tape with Plastic Cover

Electric tape alone is insufficient to protect spark plug wires from the extreme heat of the engine header.

However, you may be creative and apply plastic covers or similar insulating materials with sufficient separation around the wire. Although this is only a temporary treatment, it is the cheapest and provides adequate protection if you have no other choice.

4. Boot Sleeves

Boot sleeves are constructed of heat-resistant polymers that slide around spark plug wires. To make them fit correctly, you must add dialectic grease.

These are more of a precautionary measure. You’ll create an extra layer of protection and get the most results if you add boot sleeves, overheat shields, insulation boots, or boot protectors.

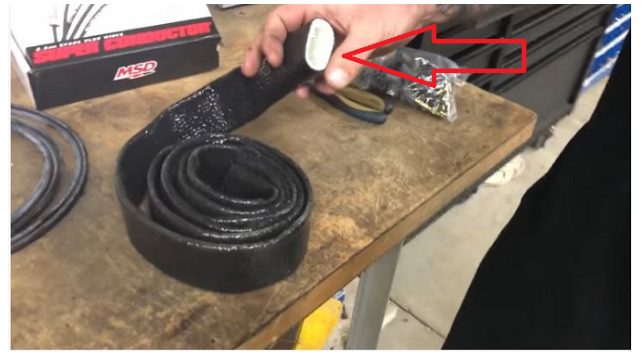

5. Fiberglass Socks

This is another solid and heat-resistant substance in many spark plug wire heat shields. They are composed of heat-insulating silicone.

The flexibility of Fiberglass socks is one of its advantages. You can use them like zip ties to keep them as far away from the engine header as feasible. The fiberglass is stronger enough to withstand the heat generated by the extended distance.

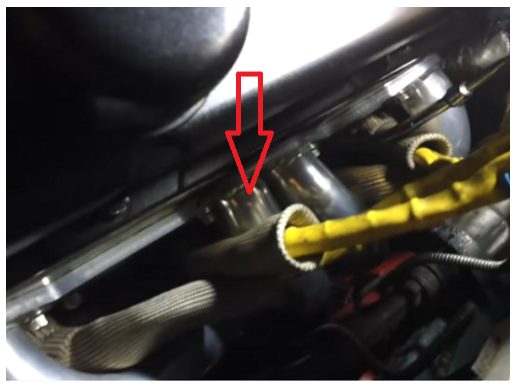

6. Heat Shields

Last but not least. These are comparable to insulative boot protectors but are composed of higher-grade materials such as titanium, basalt, fiberglass, and others that can give maximum heat protection.

Lava Fiber Heat Shield, for example, is constructed of titanium and can withstand temperatures of up to 980 °C (or 1800 °F). They have a braided construction that absorbs heat well.

Other Solutions to Protect Spark Plug Wires from Headers

Aside from direct heat resistance, there are other creative ways to shield your spark plug wires from headers.

Zip Ties

Zip ties are another excellent option to consider when it comes to the simplest way to separate cables.

These gadgets keep lines from coming into contact with hot surfaces. However, confirm the wires are appropriately secured, not worn out, or damaged by mistake.

Also, zip ties are less expensive and more widely available than this list’s other equipment and procedures.

Apply Padding

You can use a thin cloth to paddle in-between the spark plug and header. It creates more space between them, allowing air to circulate, keeping the area air. It may also absorb a lot of heat.

Maintenance

Maintaining your vehicle regularly is a great strategy to keep your spark plug wires from burning.

It is essential to visit your repair shop and inspect your car’s engine periodically. This inspection comprehensively examines all components beneath your vehicle’s hood.

These could be fixed if the technician discovered any growing issues during the examination.

Avoid Sharp Debris

Wires are easily damaged when they are near sharp objects or header edges. Any shattered component from its surroundings will absorb heat.

If you come across any damaged or frayed wires, replace them as soon as possible. Electrical tape will also assist in protecting your cords from additional damage.

Installing Spark Plug Wire Heat Shields

Heat shield installation is the most typical source of misunderstanding for household mechanics regarding spark plug wiring. It may appear straightforward, but there are several important considerations to keep in mind. Follow these simple steps to accomplish it correctly.

Step 1. Heat Shield

First, guarantee that the heat shield you purchased contains eight or more heat shields. Most engines include at least eight spark plugs, if not more.

Step 2. Installation Process

Let the engine cool down before beginning the installation process.

Step 3. Spark Plug Wires

After the engine has cooled, inspect the cylinder head and gradually remove all spark plug wires.

Step 4. Boots in Place

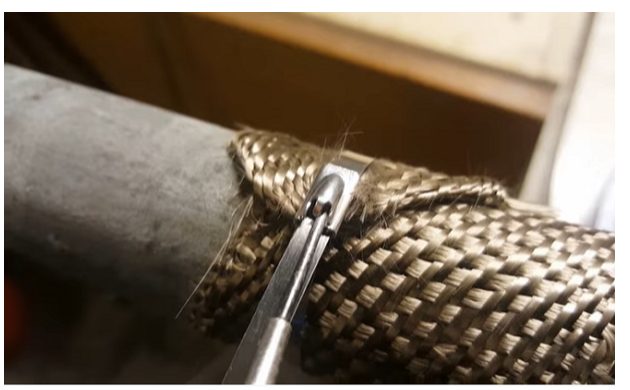

After unplugging the wires, insert them inside the heat shields. Each heat shield has a ring around the edge. It is what maintains the boots in place.

Step 5. Use Dielectric Grease

Use dielectric grease if you’re having difficulties getting the wires in properly. It allows them to enter smoothly.

Step 6. Replace the Spark Plugs

Replace the spark plugs in their original locations. The installation is now complete!

That should work for any spark plug wire installation, whether it’s insulation boots, boot sleeves, or even fiberglass socks.

What is the Best Insulation Method?

You can trust that using every insulating approach discussed is an excellent way to protect your spark plug wires. If you have the resources, it’s not a terrible idea, but it’s not required. A more strategic approach is possible.

Try the zip tie or fiberglass sock approach if you feel your wires are overly twisted and bending over the header. It pulls them away from the header, resulting in less heat contact.

Again, a heat shield or insulating boot protection technique should be used for vehicles with no insulating material on their wiring.

It’s not about doing more but rather about doing it more efficiently.

Using only one or two ways we’ve discussed will keep your spark plug wires safe.

Wrapping Up

Because of their location on the headers, spark plug wires risk overheating.

It would help if you did all possible to safeguard them using the appropriate measures. By following some of the advice we’ve provided, you may assure a longer lifespan for your wires, which will directly influence your car’s condition. (2)

Also, arrange periodic maintenance checks with your preferred technician to help determine how to keep your vehicle’s performance in top shape.

Take a look at some of our related articles below.

- How to test spark plug wires without multimeter

- How long do spark plug wires last

- How to crimp spark plug wires

References

(1) strategic approach – https://www.techtarget.com/searchcio/

definition/strategic-management

(2) car’s condition – https://www.investopedia.com/articles/

investing/090314/just-what-factors-value-your-used-car.asp

Video Reference

Carts & Quads