What is TFFN Wire? (Characteristics, Applications)

TFFN wire, an acronym for Thermoplastic Flexible Fixture Nylon, is a type of electrical wiring commonly used in residential and commercial settings.

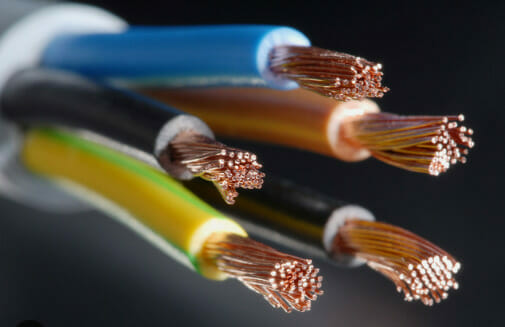

What’s special about TFFN wire is its durability and versatility. It’s made with flexible stranded copper conductors, making installing it around corners or tight spaces easy. Now, that’s something you’ll appreciate when dealing with complex installations!

In general, TFFN wire boasts these key attributes:

- A smooth outer jacket eases installation.

- Versatile usage: building, appliances, ballasts, hook-ups.

- Flame and high heat resistance ensure safety.

- Resistance to gasoline and oil

In this article, I’ll delve into more details about TFFN wires – their characteristics, uses, how they compare with other types of wires and much more.

TFFN Wire Composition

Let’s dive into the nitty-gritty of what TFFN wire is made of.

Essentially, it’s a type of electrical wire with thermoplastic insulation. The acronym TFFN stands for Thermoplastic Flexible Fixture Nylon. Each letter in that name gives us a clue about its unique properties.

‘Thermoplastic’ part means it’s constructed with material that becomes pliable or moldable at high temperatures and solidifies on cooling down. So, if you’re working in a hot environment, this wire won’t lose shape or functionality.

‘Flexible Fixture’ relates to the wire’s ability to bend without breaking. It can twist and turn around corners, making it perfect for complex wiring systems.

Lastly, ‘Nylon’ points out the outer coating material covering the wire. This nylon jacket provides extra protection against physical damages like cuts or abrasions.

You might wonder how these elements come together in a single piece of wire.

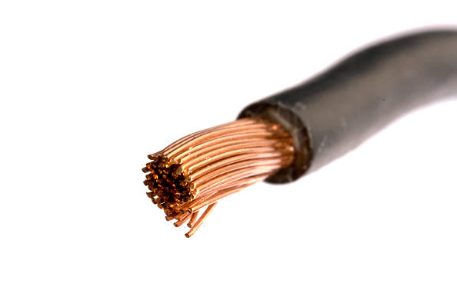

It begins with a core conductor, usually made from copper due to its excellent conductivity. This copper core is then insulated with PVC (Polyvinyl Chloride), providing resistance against heat, oil, and chemicals. Finally, the whole thing gets wrapped up in that aforementioned nylon jacket for added durability.

So there you have it! The composition breakdown of TFFN wire, an electrician’s best friend when navigating those tricky twists and turns during installations!

Unveiling the Versatility and Resilience of TFFN Wire

When it comes to electrical wiring, we’re diving into a world where flexibility, durability, and adaptability are the superheroes of the story.

Enter a versatile and robust wiring solution that will steal the spotlight in electrical installations.

1. Smooth Outer Jacket for Easy Pulling

Imagine a wire that glides through the toughest spots with grace. This wiring solution has a smooth outer jacket, making installation a breeze. No more wrestling with wires when navigating conduits or snaking them behind walls. It’s like the electrician’s secret weapon for a hassle-free job!

2. Multiple Usage Scenarios

This wire doesn’t just stick to one role; it’s a multitasking maestro:

- Building Wire 90°C: It laughs in the face of heat, perfect for buildings where temperatures can hit a scorching 90 degrees Celsius. Say hello to a wire that’s your indoor electrical MVP!

- Appliance Wire 105°C: Need a wire that can handle the heat from your trusty appliances? Look no further! This wire can take temperatures up to 105 degrees Celsius, ensuring your appliances stay cool and safe.

- Fluorescent Ballast: Lighting aficionados, rejoice! This wire is your go-to for fluorescent ballasts. It can handle the heat and conduct electricity like a pro, ensuring your lights shine bright.

- Hook-Up 90°C: Got a project with some hot situations? This wire can handle it with ease. When temperatures hit 90 degrees Celsius, your trusty sidekick ensures a secure and dependable connection.

3. Flame Resistance

Safety first! This wire is designed with flame resistance in mind. In case of unexpected fires, it won’t fuel the flames.

4. High Heat Resistance

When it comes to high temperatures, this wire doesn’t break a sweat. It’s your go-to companion, standing strong even in hot environments. Say goodbye to worries about wire hazards!

5. Gasoline and Oil-Resistant

In the industrial world, it’s no stranger to oil and gasoline. This wire laughs in the face of these substances, maintaining its strength and electrical prowess even in challenging conditions. It’s like the superhero of durability!

Whether a DIY enthusiast tackling a home project or an industrial wizard crafting complex setups, this wire is your versatile and reliable sidekick in electrical installations.

Say goodbye to wire woes and hello to a world where wiring is an adventure!

TFFN Wire Sizes and Applications

Let’s get into the heart of what makes TFFN wire great: its sizes and applications. I’m sure you’re wondering, “What on earth can I use this stuff for?”

Well, sit tight because we’re about to dive in.

Size Matters: TFFN wires come in a variety of sizes. They typically range from 18 AWG to 10 AWG (American Wire Gauge). This size variation allows them to handle different current loads effectively. So whether your project is big or small, there’s likely a TFFN wire that fits the bill.

| Size (AWG) | Maximum Amps |

|---|---|

| 18 | 14 |

| 16 | 18 |

| 14 | 25 |

| 12 | 30 |

| 10 | 40 |

Versatile Applications: Now, onto the fun part – applications! Due to their versatility and durability, TFFN wires are used quite extensively.

Here’s a closer look at their versatile roles:

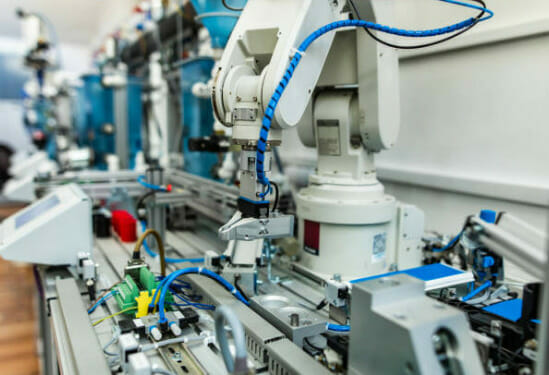

- Machinery Mastery: They’re commonly employed in control circuits for machinery where flexibility is essential. These wirings need constant adjustment and rerouting. No problem! With their thermoplastic insulation that withstands heat up to 90 degrees Celsius, these wires are game for anything!

- Lighting Brilliance: They also find use in lighting fixtures and appliances due to their high-temperature endurance.

- Cool and Reliable: You’ll even spot them used as internal air conditioning wiring.

However, it’s important to remember that they’re unsuitable for outdoor settings or direct burial because they lack the necessary protection against moisture and environmental damage.

So there you have it! The diverse world of TFFN wires laid out before you – from various sizes adjusting according to your needs to their myriad uses across multiple industries.

Electrical Performance

I’ve got to tell you, the electrical performance of TFFN wire is something.

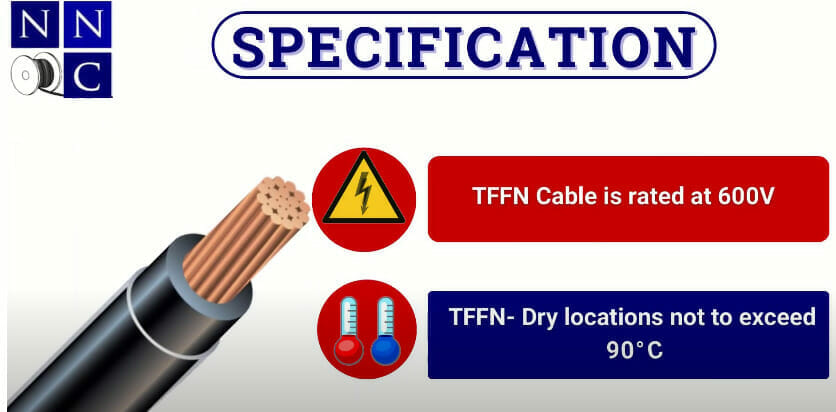

It’s designed to operate efficiently in temperatures up to 90 degrees Celsius (194 Fahrenheit for those who prefer it). Now, that’s pretty hot! This wire can withstand these high temperatures without any loss in performance or safety.

Impressive Voltage Endurance:

Let me give you an idea about its voltage rating. TFFN wire has a solid voltage rating of 600 volts. What does this mean? Well, it means it can handle some serious power flow without breaking a sweat.

Resilience in the Face of Adversity:

One thing I find impressive about TFFN wire is its resistance to various environmental factors. It’s got fantastic resistance against acid, oil, and coolant fluid exposure. It’ll stand tall and continue delivering top-notch performance.

Efficiency-Boosting Low Impedance:

Impedance refers to a circuit’s opposition to a current when voltage is applied. The lower the impedance, the smoother the current flows through the circuit. Guess what? Our superstar TFFN wire boasts low impedance levels, making it ideal for efficient electricity transmission applications.

Safety Through Insulation Thickness:

Lastly – insulation thickness plays a crucial role in ensuring safe and efficient operation of electrical systems where TFFN wires are used. Typically, these wires come with an insulation thickness of around .015 inches – providing an excellent barrier between the conducting material and outer-world interference.

So there you have it – from temperature toughness to sturdy voltage handling, from environmental resilience to low impedance levels, from perfect insulation thickness maintaining safety – TFFN Wire has all bases covered!

Safety Considerations

When it comes to TFFN wire, there’s more than meets the eye. This isn’t just about knowing what it is and how it works – safety matters too.

1. Gauge Compatibility:

- When used properly, TFFN wire is a powerhouse, but misuse can lead to problems. For instance, overloading the circuit using a wire with an inadequate gauge for the load can cause overheating and potential fire hazards. It’s crucial to respect the recommended ampacity of each specific wire size.

2. Meticulous Installation:

Let’s talk installation. I can’t stress enough the importance of proper insulation and grounding when installing TFFN wires. Without these precautions:

- Electrical shocks could occur

- Overheating might happen

- Fire risks increase

These are serious issues you’ll want to avoid at all costs.

3. Routine Inspection:

- Let’s keep your TFFN wiring in tip-top shape! Please give it a friendly checkup every now and then. Look out for any sneaky signs of damage, wear, or tears. And here’s the superhero part: if you spot anything amiss, don’t hesitate! Jump into the action and fix it up pronto. It’s all about keeping your space safe and sound!

4. Appropriate Application:

- Remember that TFFN wires aren’t suited for every application out there. They have their strengths – like being resistant to certain oils and coolants – but they’re not designed for outdoor use or in areas with high moisture levels.

So there you have it! A quick run-down on safety considerations when dealing with TFFN wires.

It isn’t just good knowledge – it’s essential know-how if we want our electrical projects to run smoothly (and safely).

TFFN vs. Other Wiring Types

| Wiring Type | Main Application | Key Distinction |

|---|---|---|

| TFFN | Commercial/Industrial | High flexibility, suitable for conduit and cable trays in dry locations. |

| THHN | Commercial/Industrial | Offers heat resistance, applicable in both dry and wet locations. |

| Romex® | Residential | Designed for residential use, non-metallic sheathed cable. |

| UF-B | Residential/Outdoor | Suitable for direct burial without additional protection. Requires protective conduit if used outdoors. |

References

Studies:

- Electrical Wiring Safety Studies. https://ehs.washington.edu/fire-life/basic-electrical-safety

- Wire Insulation Material Studies. https://www.osti.gov/etdeweb/biblio/5383516

- Electrical Conductor Studies. https://onlinelibrary.wiley.com/doi/full/10.1002/pssa.202000704

- Heat Resistance in Wiring Studies. https://www.ucc.ie/en/physics/study/undergraduate/thelaboratories/firstyearphysicslabs/resistanceofawire/

- Electrical Wiring Standards and Practices. https://status.restek.wwu.edu/51910/v/file/visit?PDF=electrical-wiring-practice-and-2.pdf

Organizations:

- National Electrical Contractors Association (NECA). https://www.necanet.org/

- International Association of Electrical Inspectors (IAEI). https://www.iaei.org/

- Institute of Electrical and Electronics Engineers (IEEE). https://www.ieee.org/

- National Fire Protection Association (NFPA). https://www.nfpa.org/

- Underwriters Laboratories (UL). https://www.ul.com/solutions

Books:

- “Wiring Simplified” by H.P. Richter and W.C. Schwan

- “Electrical Wiring Residential” by Ray C. Mullin and Phil Simmons

- “NEC 2020: National Electrical Code” published by NFPA

- “Electrical Engineering: Principles and Applications” by Allan R. Hambley

- “Electrical Wiring Commercial” by Phil Simmons and Ray C. Mullin

Website Resources:

- OSHA Electrical Safety. https://www.osha.gov/electrical

- IEEE Standards Association. https://standards.ieee.org/

- NFPA. https://www.nfpa.org/NEC/electrical-codes-and-standards

Videos References:

Nassau National Cable