SOOW Wire Defined (Usage & Best Practices)

You might’ve encountered the term ‘SOOW wire.’ You’re probably wondering, “What’s so special about it?”.

SOOW wire is a common portable cord used in various industrial settings. It’s hailed for its durability and flexibility. The name is an acronym for Service Oil-resistant insulation and jacketing, Weather resistant.

Let’s go into more detail below.

The Evolution of SOOW Wire: A Historical Glimpse

As we marvel at the prowess of SOOW wire today, it’s fascinating to trace its roots and understand its evolution. The history of electrical wiring has been a journey of innovation, safety enhancements, and addressing diverse industrial needs.

- Late 19th Century: Electrical wiring emerges, using rudimentary cloth and paper as insulation, with prevalent safety concerns.

- Early to Mid-20th Century: Rapid industrialization demands more robust wiring solutions. Engineers begin exploring durable insulation materials.

- Mid-20th Century: Specialized rubber compounds revolutionize wire insulation, offering resistance to oils, chemicals, and extreme temperatures.

- Late 20th Century: The birth of SOOW wire. Designed with Service, Oil-resistant insulation and jacketing, and Weather resistance, it has become the industry’s answer to resilient and safe wiring for challenging environments.

- Today: SOOW wire is a staple in diverse applications, showcasing how far we’ve come from basic cloth-wrapped wires to today’s pinnacle of wiring durability.

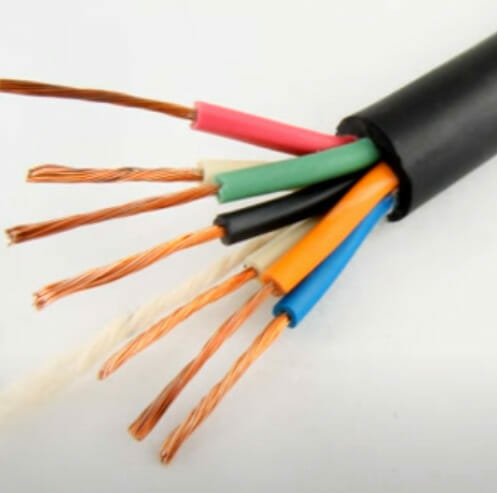

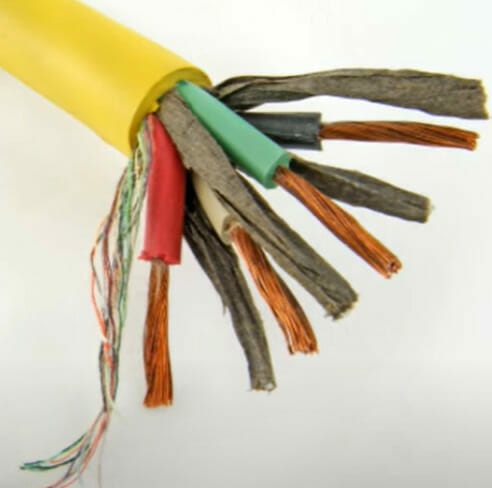

SOOW Wire: Construction, Composition, and Key Features

I’m sure you’re wondering, “What’s SOOW wire?” Well, let me break it down for you. It’s a portable cord type that is often used in industrial settings. The acronym SOOW stands for Service Oil-resistant Insulation and Oil-resistant Jacket with Weather resistant properties.

Here are some standout specifications of SOOW wire:

| Feature | Specification |

|---|---|

| Core Material | Constructed with strands of fully annealed bare copper, which gives them excellent conductivity. |

| Insulation | Available in sizes ranging from 18 AWG up to 2 AWG. |

| Outer Jacket | The outer jacket of these cables is also oil-resistant because it’s composed of Chlorinated Polyethylene |

| Temperature | Able to withstand temperatures between -40°C to 90°C. |

| Voltage | Typically rated up to 600 volts. |

| Sizes | Available in sizes ranging from 18 AWG all the way up to 2 AWG. |

| Conductor Count | 2 to 40 conductors per cable |

Applications and Usage

So, what’s the real-world use of SOOW wire? Well, let me tell you! This versatile player finds its place in various industries and applications.

It’s the unsung hero in many setups, delivering power efficiently and safely where needed.

| Application Area | SOOW Wire Usage |

|---|---|

| Industrial Sector | Heavy machinery needs a reliable power source to keep production lines humming along. Its robust construction makes it capable of handling high-voltage currents without sweat. |

| Live Performances | Connecting speakers, lights, and other stage equipment to their power sources. These wires are tough enough to withstand foot traffic, repeated coiling and uncoiling, and exposure to outdoor elements. |

| Construction Sites | Every piece of equipment there relies on SOOW wiring for operation. It can withstand rough handling typical on such sites, making it an indispensable asset. |

| Marinas & Shipyards | With its water-resistance abilities, SOOW cable ensures smooth sailing by providing secure connections for navigation systems, lighting fixtures amongst others onboard boats or ships. |

Advantages and Disadvantages of Using SOOW Wire

SOOW wire, distinguished by its resilience and versatility, has emerged as an industry favorite for demanding electrical applications. Balancing an impressive range of advantages, from durability to flexibility, with a few caveats to consider.

Let’s delve into what sets this wire apart in electrical cabling.

| Aspect | Description | Deep Dive |

|---|---|---|

| Advantages | ||

| Durability | High resistance to wear and tear. | Crafted with materials designed to endure physical damages from foot traffic, being dragged across surfaces, or facing harsh environmental conditions. |

| Versatility | Functions effectively in varied environments. | It can operate indoors in industrial settings or outdoors in event venues due to its inherent qualities, such as resistance to various elements. |

| Temperature Resilience | Operates from -40°C to 90°C. | Ensures safety and functionality in a diverse range of climates and working conditions. |

| Flexibility | High adaptability around obstacles. | It is priced higher than many other wire types. |

| Easy Identification | Color-coded conductors for easy circuit recognition. | Streamlines troubleshooting, maintenance, and installation processes, reducing potential errors during electrical setups. |

| Disadvantages | ||

| Weight | Heavier than other wire types. | The robust construction makes transportation and maneuvering challenging, especially with long wire lengths. |

| Cost | It is not always necessary for minor, controlled applications. | Given its premium features, SOOW wire tends to be more expensive than wires with fewer resistances. Budget-sensitive projects might consider the initial cost a potential challenge. |

| Overengineering for Simple Tasks | It is not always necessary for minor, controlled applications. | Using SOOW for minor tasks in controlled environments might be excessive. It’s like using a sledgehammer to crack a nut, where a simpler, less expensive wire could suffice. |

Wire Types Comparison: SOOW vs. SJOOW vs. SJTOW

You may be wondering how SOOW stacks up against other wire types. Well, let’s dive right in. Some interesting distinctions emerge when we pit SOOW against types like SJOOW and SJTOW.

SOOW: It’s built for tougher conditions with thicker insulation than its counterparts. This makes it more durable and better suited for industrial applications or harsh environments where resistance to oil, water, and weather is critical.

SJOOW: While similar, it has a thinner jacket construction than SOOW. This makes it lighter but less resistant to physical damage.

SJTOW: Offers enhanced water resistance but lacks the oil-resistant properties found in both SJOOW and SOOW wires.

Let’s break down the fundamental differences between these three to help you make an informed decision:

| Wire Type | Jacket Thickness | Resistance Features | Voltage Rating | Places with high moisture lack oil resistance |

|---|---|---|---|---|

| SOOW | Thickest | Oil, Water, Weather | High | Harsh environments, industrial applications |

| SJOOW | Thinner | Limited to Water | Medium | Lighter tasks with less physical damage |

| SJTOW | Moderate | Enhanced Water-Resistance | Medium | Places with high moisture, lacks oil-resistance |

Safety and Compliance of SOOW Wire

Let’s talk about safety because it’s a big deal regarding SOOW wire. The “S” in SOOW stands for “service,” but I like to think of it as standing for “safety.”

These wires are designed with an outer jacket resistant to water, oil, sunlight,, and weather. This isn’t just a nice-to-have feature – it’s a must-have for ensuring the safety of everyone who comes into contact with this wiring.

Beyond robust construction, SOOW aligns with critical industry standards:

- Compliance: Adheres to NEC and OSHA requirements, fulfilling the National Electrical Code (NEC) Article 400 and OSHA standards for portable cords and cables.

| Compliance Mark | Description |

|---|---|

| UL Listed | Universal Laboratories has given its seal of approval after thorough testing. |

| CSA Certified | The Canadian Standards Association has checked it out, too. |

| Msha Approved | It even got the thumbs up from the Mine Safety and Health Administration. |

Regarding voltage ratings:

- SOOW: Rated at 600V, indicating its safe electrical pressure threshold.

Maintenance and Care

SOOW wires are renowned for their durability and resilience but benefit from proper care like any electrical equipment. Here’s how to ensure the longevity of your SOOW wire:

- Regular Inspection: Periodically check the entire length of the wire for any visible damage like cuts, abrasions, or deformities.

- Avoid Overloading: Even though SOOW wires are tough, pushing them beyond their voltage rating can decrease lifespan. Always ensure you’re within the recommended electrical load.

- Proper Storage: If the wire isn’t used, coil it loosely and store it in a dry place, away from direct sunlight or extreme temperatures.

- Clean Gently: If your wire becomes dirty, wipe it down with a damp cloth and mild detergent. Avoid using any harsh chemicals that might degrade the insulation.

- Replacements: If any section of your wire becomes damaged, consider replacing that segment or the entire wire to ensure safety and optimal performance.

Safety Tips for SOOW Wire

1. Power Precautions: Ensure the power source is turned off before handling or installing the SOOW wire. This reduces the risk of electric shocks.

2. Proper Handling: Use gloves when working with SOOW wire, especially in industrial environments, to protect against cuts or abrasions.

3. Avoid Overloading: Never exceed the voltage rating of the wire. Overloading can lead to overheating and potential fire hazards.

4. Regular Inspections: Periodically inspect the wire for any signs of damage, wear, or tear. Damaged wires can pose safety risks and should be replaced immediately.

5. Keep Away from Flammables: While SOOW wire is durable, keeping it away from flammable materials is crucial to prevent fire-related incidents.

6. Proper Installation: Ensure the wire is securely installed and anchored, avoiding tripping hazards.

7. Grounding: Always ensure that SOOW wire is correctly grounded to prevent electrical shocks, especially in industrial applications.

8. Child and Pet Safety: If used in areas accessible to children or pets, ensure the wire is out of reach. Children and pets might unknowingly damage the wire or put themselves at risk.

9. Follow Manufacturer’s Instructions: Always adhere to the manufacturer’s guidelines when installing, using, or maintaining SOOW wire.

10. Stay Informed: Regularly update yourself with safety standards and best practices related to electrical wiring. Knowledge is a key defense against potential hazards.

Environmental Impact of SOOW Wire

In today’s rapidly evolving industrial landscape, our tools and materials play a pivotal role in efficiency and safety and the broader context of environmental sustainability.

1. Durability and Waste Reduction:

- SOOW wires are designed to last longer, reducing the need for frequent replacements. This can lead to decreased electronic waste, which benefits the environment.

2. Material Usage:

- SOOW wires use specialized rubber compounds for insulation. While these compounds provide excellent insulation and protection, they are not as biodegradable as other materials. This emphasizes the importance of proper disposal.

3. Recycling:

- While copper, often used as the core material in SOOW wires, is recyclable, the rubber sheathing may not be. It’s essential to strip the copper and recycle it separately.

4. Energy Consumption:

- Due to their robust design, SOOW wires may lead to efficient electricity conduction, potentially reducing energy losses and contributing to energy conservation.

5. Manufacturing Footprint:

- Like many industrial products, the production of SOOW wires has an environmental footprint. This includes energy consumption during manufacturing and the extraction and processing of raw materials.

Frequently Asked Questions

- Can I use SOOW wire for residential purposes?

- While SOOW is primarily designed for industrial settings, it can be used in residential scenarios requiring durable wiring. For basic home applications, it might be over-engineered.

- Are there specific connectors or plugs for the SOOW wire?

- While SOOW wire is compatible with various connectors or plugs, always ensure they’re rated for the wire’s voltage and intended conditions.

- Is SOOW wire fire-resistant?

- While it’s designed to be durable and resistant to various conditions, it isn’t classified as fire-resistant. Always ensure proper safety precautions in fire-prone areas.

- Can SOOW wire be buried underground?

- While weather-resistant, direct burial is not recommended without additional protective conduit or sheathing.

- How often should I inspect my SOOW wire for wear and tear?

- For optimal safety and performance, periodic inspections are advised, preferably every 6-12 months or after heavy usage.

- Does SOOW wire come in different colors?

- The outer jacket is typically black, but the internal conductors come in various colors for easy circuit identification.

- What’s the maximum length I should use for a single run of SOOW wire?

- The maximum length depends on the load, voltage drop considerations, and specific application requirements. Always consult an electrician or refer to electrical guidelines when planning extended runs.

References

Website Resources:

- OSHA (Occupational Safety and Health Administration). https://www.osha.gov/

- Electrical Contractor Network. https://www.electrical-contractor.net/

- 12 AWG SOOW Portable Cord. https://www.amazon.com/SOOW-Portable-Conductor-Power-Jacket/dp/B08JHBF46X/

Video Resources:

Helena Sell

Nassau National Cable

Electrician U

Allied Wire and Cable

Todd Wren