What is THHN Wire? (A Comprehensive Guide)

Curious about what the term THNN means and its functions?

THHN wire stands for “Thermoplastic High Heat-resistant Nylon-coated,” signifying its key attributes. It offers durability, heat resistance, and a smooth surface for easy installation. THHN wire consists of a solid or stranded copper conductor, PVC insulation, and a nylon coating, making it an excellent choice for various electrical wiring applications with high heat and adverse conditions.

Throughout this article, we’ll dive deeper into the properties and uses behind this technical jargon and explain why it matters in the grand scheme of electrical wiring.

A Brief History of THHN Wire

THHN wire development aligns with the evolution of electrical wiring. As electricity use increased in the late 19th and early 20th centuries, so did the demand for safe, efficient wiring.

Initially, copper emerged as a prime conductor but needed insulation to prevent oxidation. Early insulations like rubber or cloth had limitations, which led to the adoption of PVC, a thermoplastic, offering superior insulation and heat resistance.

The innovation of adding a nylon coating provided extra mechanical protection and facilitated wire pulling through conduits, marking the birth of modern THHN wire.

Its usage has grown alongside electrical system advancements, now spanning residential to industrial applications. Its exceptional properties make it a preferred choice for many electricians and engineers today.

Definition of THHN Wire

Let’s examine what THHN stands for. The acronym indicates the wire’s key attributes: “Thermoplastic High Heat-resistant Nylon-coated.”

“Thermoplastic” is the type of insulation used, characterized by its ability to be repeatedly heated and cooled without deformation.

This feature translates to durability and long-term reliability in diverse settings, particularly where temperature fluctuations are common.

“High Heat-resistant” underlines one of the wire’s standout features—its ability to maintain optimal function under elevated temperatures.

This quality makes THHN wire an ideal candidate for environments or applications where high heat is present or expected.

The term “Nylon-coated” points to a protective outer layer encapsulating the wire.

This nylon sheath plays a dual role—it enhances the wire’s overall durability and facilitates the process of pulling the wire through conduits, owing to its smooth surface.

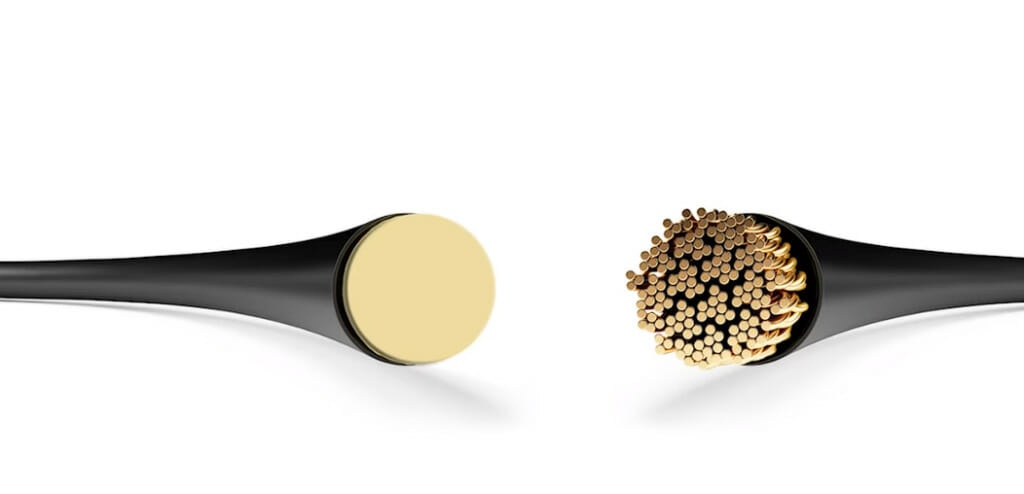

THHN wire typically consists of a solid or stranded copper conductor underneath these protective layers. Before applying the nylon jacket, this conductor is first wrapped in PVC (Polyvinyl Chloride) insulation.

The copper core ensures excellent electrical conductivity, while the PVC insulation and nylon coating work in tandem to protect the wire from environmental factors and physical wear.

This structural combination positions THHN wire as a resilient and reliable choice in electrical wiring, ensuring efficient power delivery where it’s needed most.

THHN Wire Composition

| Component | Material | Function |

|---|---|---|

| Conductor | Copper (Solid or Stranded) | Provides excellent electrical conductivity, allowing the wire to carry an electric current efficiently. |

| Insulation | PVC (Polyvinyl Chloride) | Provides resistance against environmental factors and physical wear, protecting the copper conductor. |

| Outer Jacket | Nylon | Enhances the wire’s durability and facilitates installation by enabling the wire to slide easily through conduits. |

Properties of THHN Wire

When it comes to the properties of THHN wire, a few key characteristics distinguish it from other types of wiring. These properties combine to make it versatile and durable for various applications.

Here are the standout properties:

- Heat Resistance: A signature trait of THHN wire is its impressive heat resistance. With the ability to handle temperatures up to 90 degrees Celsius (194 degrees Fahrenheit) in dry locations, it’s the go-to choice in settings with high operating temperatures.

- Resilience to Adverse Conditions: The PVC insulation and nylon jacket contribute to THHN wire’s resistance against moisture, gasoline, and specific chemicals. This resilience makes the wire an enduring contender for industrial or outdoor installations where it might face harsh conditions.

- Ease of Installation: THHN wire’s nylon jacket doesn’t just offer protection—it also creates a smooth surface. This eases pulling the wire through conduits, making installations more efficient.

- Variety of Gauge Sizes: THHN wire is available in a spectrum of gauge sizes per the American Wire Gauge (AWG) system. It ranges from the larger 1000 MCM wire down to the smaller 14 AWG wire, providing a fit for diverse power needs and installation environments.

- Color-Coding for Safety: THHN wires come color-coded, simplifying identification. This color-coding system contributes to safe and efficient use, particularly in complex wiring systems.

Each of these properties contributes to the functionality, adaptability, and safety of THHN wire, making it a suitable choice for a broad range of applications, from residential to commercial and industrial contexts.

Uses of THHN Wire

Due to its unique properties, THHN wire finds a place in various applications, underlining its versatility. Here are some primary uses:

- Conduit and Cable Trays: A primary application of THHN wire is within conduit and cable trays. These are used for service, feeder, and branch circuits in diverse residential, commercial, and industrial settings.

- Lighting Fixtures: Given its reliable conductivity and heat resistance, THHN wire is often chosen for wiring up lighting fixtures. Its robust structure ensures consistent performance, even when used for extensive periods.

- Heating Units and Air Conditioners: THHN wire’s resistance to high temperatures makes it ideal for powering heating units and air conditioning systems. These applications often require wire that can withstand the heat generated without compromising performance.

- Control Circuits: THHN wire is used in control circuits for various appliances and machinery. Its reliable conductivity and durability ensure that the control circuit functions optimally.

- Machine Tools: Machine tools often operate in challenging environments where they may be exposed to moisture or high temperatures. THHN wire, with its robust insulation and heat resistance, proves to be an excellent choice for such applications.

In general, THHN wire is suitable for use in dry locations where temperatures do not exceed 90°C or in wet locations where temperatures don’t exceed 75°C.

This adaptability enables THHN wire to function effectively in various settings, from household appliances to commercial machinery and complex industrial systems.

Comparison to Other Wires

| Wire Type | Cost | Efficiency | Durability | Applicable Use Cases |

|---|---|---|---|---|

| THHN | Moderate | High | High | Conduits, cable trays, lighting fixtures, heating units, air conditioners, control circuits, machine tools |

| TFFN | Low | Moderate | Moderate | Indoor use, lighting fixtures, control circuits, and machine tools in dry locations |

| UF-B | High | Moderate | High | Direct burial, outdoor lighting, pumps |

| NM-B | Low to Moderate | Moderate | Low to Moderate | Indoor residential wiring in dry locations |

| XHHW | High | High | High | Wet or dry locations in conduits or other recognized raceways for services, feeders, and branch circuit wiring |

Note: The comparison is made in general terms. The actual cost, efficiency, durability, and applicable use cases can vary based on the specific wire brand, local code requirements, and the particular application for the wire.

Compliance and Certifications for THHN Wire

| Certification | Organization | Relevance | Standard | Description |

|---|---|---|---|---|

| UL | Underwriter Laboratories | United States | UL 83 | Standards for thermoplastic-insulated wires and cables. Indicates that the THHN wire has passed tests for safety and performance. [Wire & Cable Certificate] |

| CSA | Canadian Standards Association | Canada | CSA C22.2 No. 75 | Standards for thermoplastic-insulated wires and cables. Indicates that the THHN wire meets applicable safety and performance standards in Canada. [Testing Certification] |

Safety Tips and Precautions for Using and Installing THHN Wire

| Safety Tips and Precautions | Description |

|---|---|

| Correct Installation | THHN wire should be installed according to National Electrical Code (NEC) guidelines. It’s usually pulled through conduit, and the wire’s nylon jacket facilitates this process. |

| Limitations Awareness | THHN wire is suitable for use in dry locations with temperatures not exceeding 90°C and wet locations with temperatures not exceeding 75°C. Going beyond these limits could lead to wire damage or malfunction. |

| Professional Installation | Ensure the power is off before working with electrical wiring to prevent electric shock. Use a voltage tester to verify. |

| Personal Protective Equipment (PPE) | When working with electrical wires, wear appropriate PPE. This includes insulated gloves, safety glasses, and flame-resistant clothing. |

| Power Off | Always ensure the power is off before working with electrical wiring to prevent electric shock. Use a voltage tester to verify. |

References

Organizations:

- National Electrical Manufacturers Association (NEMA). https://www.nema.org/

Books:

- “Electrical Wiring Residential” by Ray C. Mullin and Phil Simmons

Websites:

- Copper Development Association Inc. (CDA). https://www.copper.org/

- The Engineering Toolbox. https://www.engineeringtoolbox.com/index.html

Video Reference

Border States