What is CU Wire? (Guide for Beginners)

Today, we’re diving into the world of CU Wire, or as you might know it – Copper Wire.

Copper wire is pretty much everywhere, and yet, it’s easily overlooked. But without it, we’d be in a real jam. It plays a crucial role in electricity transmission due to its high electrical conductivity. That means copper wire helps power almost everything around us – from our homes to our gadgets!

So sit tight because we’ll explore CU wire, how it came about, and why it’s important for us all. And trust me, by the end of this journey, you’ll see copper wires in a whole new light! Let’s get started!

Unraveling the Mysteries of CU Wire

CU stands for Copper. So, we’re talking about copper wires.

Why Copper? It’s all about conductivity. Copper is a superstar when it comes to conducting electricity. Silver has the second-highest electrical conductivity of any element (only silver beats it!), but it is way too expensive for everyday use.

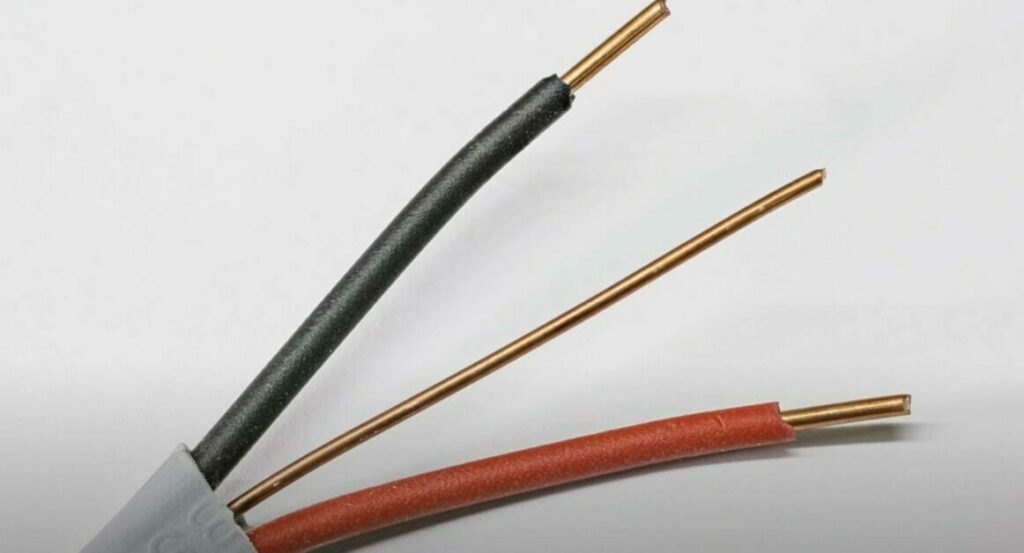

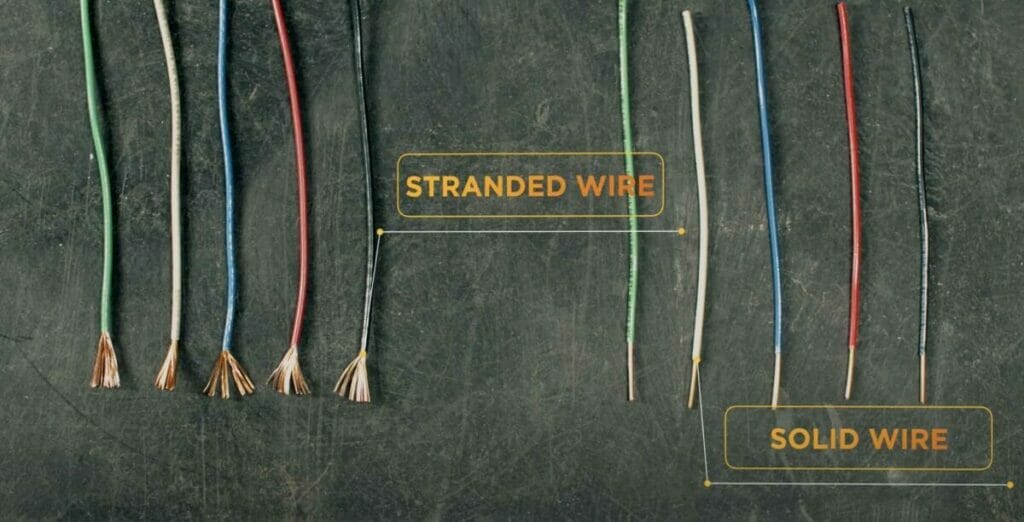

Like most things, though, not all copper wires are created equal. There are two main types: solid and stranded.

Let me break it down for you:

- Solid CU Wire: This one has a single piece of copper wire core. It’s tough stuff – perfect for permanent installations requiring a sturdy connection.

- Stranded CU Wire: Here, we’ve got many thin strands of Copper twisted together into one wire. Because it’s more flexible than solid wire, this type is great for mobile or portable applications.

Now, let’s talk numbers because they matter when choosing the right CU wire.

| Type | Diameter | Usage |

|---|---|---|

| Solid | 0.5-10mm | Permanent Installations |

| Stranded | 0.09-6mm | Portable Applications |

As a rule of thumb, remember: the larger the wire’s diameter–whether solid or stranded – the higher its current carrying capacity will be.

Isn’t Copper amazing? With its excellent conductivity and flexibility options (thanks to both solid and stranded versions), it’s no wonder that CU Wire plays such an important role in our daily lives – powering up everything from your coffee machine to your smartphone!

The Composition and Production of CU Wire

The production process behind CU wire isn’t too complicated, either. Raw copper ore goes through several stages before becoming the shiny, flexible wire we’re familiar with.

- Mining: The first step involves digging up raw copper ore from the earth.

- Purification: The mined ore then undergoes refinement to separate pure Copper from unwanted materials.

- Melting: Once purified, the resulting substance gets heated until it liquefies.

- Casting: The molten Copper is cast into thick rods or bars known as billets or cakes.

- Drawing: These chunks are then drawn out and reduced into thin wires.

Pretty cool right?

And because no article would be complete without a little data love-fest (I know how much you guys enjoy the numbers!), here’s a quick look at some interesting facts:

| Fact about Copper | Value |

|---|---|

| Atomic number | 29 |

| Melting point | 1984°F |

- Humans have used Copper for over 10,000 years!

- It’s one of few metals that doesn’t degrade after being recycled – meaning old CU wires can become new ones!

A Look at the Uses of CU Wire in Everyday Life

One huge use of CU wire is power generation. Do you know those big power lines hanging high above your head? Yep, they’re most likely made of copper wires.

Due to its excellent conductivity properties, Copper often transmits electricity over long distances.

Then there’s electronics. That smartphone you can’t live without? The computer I’m typing on right now? They’ve both got their fair share of copper wiring inside them, too!

Even in construction, CU wire plays a crucial role. Many homes and buildings use copper wiring for electrical systems because it’s durable and reliable.

- Power Generation

- Electronics

- Construction

Now don’t get me started about how essential CU wire is in cars, or we’ll be here all day!

But here are some quick facts:

| Industry | Copper Wire Usage |

|---|---|

| Power Generation | High |

| Electronics | Very High |

| Construction | Moderate |

In short (and trust me when I say this), life without Copper would look very different.

The Advantages and Disadvantages of Using CU Wires

CU wires, or copper wires, have been a major player in electrical wiring for ages. And there’s a good reason why they’re still popular today!

First off, Copper is an excellent conductor. It means electricity flows through it easily, making it ideal for electrical wiring. Have you ever noticed how quickly your appliances power up? That’s Copper doing its magic!

Another big plus for our friend copper is its durability! These wires can withstand extreme conditions without losing their functionality. Who wouldn’t want a tough guy like that handling their electricity?

But hold on a minute! Before we get too carried away singing praises to Copper, let’s look at the flip side too.

One of the main disadvantages of using CU wires is cost. Yes, folks, quality comes with a price tag. Copper is more expensive than its alternatives, such as aluminum.

And then there’s the issue of weight. While we are all for durability and toughness in our wires, this also means they’re heavier than other wire types.

So here’s what we’ve got:

| Advantages | Disadvantages |

|---|---|

| Excellent Conductor | Costly |

| Durable | Heavy |

If you want superior conductivity and durability in your electrical wiring, go for Copper! But remember – it will cost you both money and weight.

Don’t worry, though; no one said decision-making was easy! Weighing these pros and cons should help you make an informed choice when selecting your wiring type.

Comparing Copper (CU) Wires to Other Types of Wires

Copper is the go-to material for most electrical wiring because it has excellent conductivity. It’s also pretty affordable, which makes it even more popular. However, not all wires are created equal, and some worthy contenders are out there.

Aluminum wires, for instance, have been gaining traction lately. They’re lighter than Copper and cheaper too. But here’s the kicker – they’re not as good when carrying current over long distances because aluminum has only 61% of Copper’s conductivity!

On another note, we can’t forget about silver wires. Silver tops Copper with superior electrical conductivity, but there’s a catch – it’s way more expensive! So silver might not be your best choice unless you have deep pockets or need high-frequency applications like antennas and RF connectors.

Then there’s gold wire — yep, you heard me right — gold! This flashy metal isn’t just for jewelry; it’s used in certain electronics due to its resistance to corrosion and tarnish. The big downside? You guessed it: price!

Let’s lay down some stats:

| Wire Type | Conductivity (as % of Copper) | Price (Relative) |

|---|---|---|

| Aluminum | 61% | Cheaper |

| Silver | 105% | More costly |

| Gold | 70% | Most expensive |

- Copper: Excellent conductivity + Affordable

- Aluminum: Good enough for short ranges + Economical

- Silver: Best conductor but pricey

- Gold: Durable + Fancy but super costly

So when choosing between these metals for wiring purposes, remember this golden rule – it all boils down to the specific needs of your project. Keep in mind both the advantages and costs associated with each option. And hey! Whatever wire type you choose, ensure it meets those requirements nicely without breaking the bank.

How to Choose the Right Type of CU Wire for Your Needs

So, you’re on the hunt for some copper wire, huh? Well, let’s dive right in. Now, when you’re selecting a CU wire (that’s short for Copper), there are a few things you have to keep in mind.

Firstly, a gauge is key here. The gauge of the wire determines its thickness – basically, how big it is. Just remember: the smaller the gauge number, the thicker the wire. It’s a bit backward, but that’s just how these things work!

| Gauge Number | Wire Thickness |

|---|---|

| 10 | Thick |

| 24 | Thin |

Secondly, think about your project and what it needs. If we’re talking something like home wiring or electrical projects – where safety is crucial – you’ll want an insulated wire to prevent nasty shocks.

For more artistic endeavors like jewelry-making or sculpture? Bare Copper could be your best friend here! It’s flexible and easy to twist into whatever shape your heart desires.

Next up: stranded or solid? Solid wires are just that – one solid piece of metal running through them – perfect for situations requiring rigidity and strength. Stranded wires are made up of several small strands twisted together, so they’re super flexible! Great if you need something a little less stiff.

Lastly, consider the cost. Copper isn’t cheap, my friends! But don’t let that scare you away because this stuff lasts!

So that’s all I got for you today. Thanks for sticking around till the end. And next time you flip a switch or plug in your laptop charger? Maybe give a little nod to those humble copper wires making it all happen!

Stay curious, my friends–and until next time… Keep learning!

References

Organizations:

- International Copper Association (ICA). https://copperalliance.org/

- Institute of Electrical and Electronics Engineers (IEEE). https://www.ieee.org/

Books:

- “Copper: Its Mining and Use Through the Ages” by Robert Raymond Raymond

- “Copper Wire Handbook” by Anixter

Website Resources:

- Copper Development Association (CDA). https://www.copper.org/

- Electrical Engineering portal website. https://electrical-engineering-portal.com/

Video References:

Civil Engineering Forum

NaLac Technique

Empowered Electric

Technical Kafi