What Gauge Wire for Pool Pump? (Expert Weighs In)

By the end of this guide, you should be able to completely understand what wire gauge to use for your pool pump.

Pool pumps require an adequate voltage and amperage supply to function optimally. The wire gauge used to ferry these electronics must be able to accommodate them. Otherwise, the heat generated by the amperage may sabotage the activity of the electrical motor. So, the wire gauge size will depend on the amperage and voltage of the power supply.

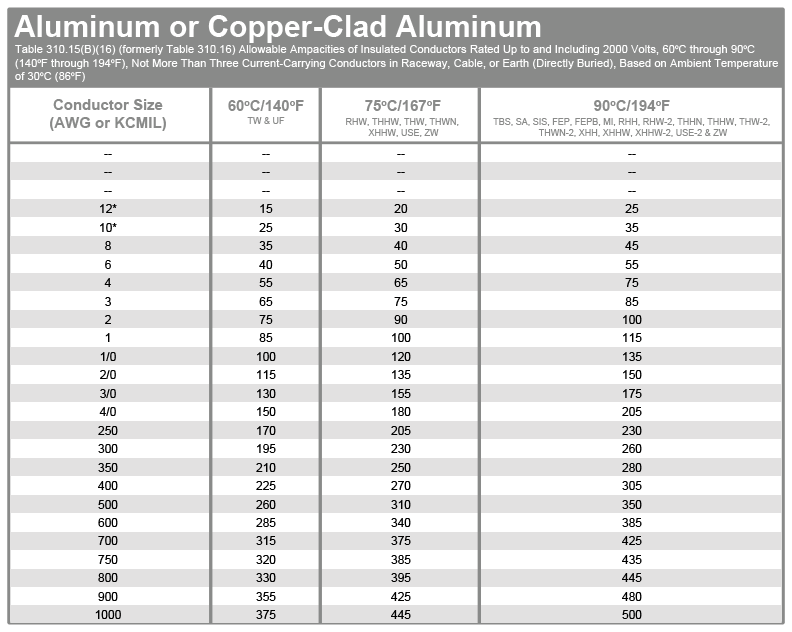

In general, the wire gauge required to supply power to a pool pump depends on many factors. But the wire gauge is often in the range of eight to sixteen. Amperage and voltage supply from the power source are the main factors. High amperage requires thicker wires. The other factors include material and the length of the run. The best material for a pool pump wire is copper which has low resistance. Then, if the length of the run is large, use thicker wires to supply power to your pump.

We’ll go into more detail below.

Factors to Consider when Choosing a Wire Gauge for a Pool Pump Motor

Material

There is only one correct choice of material for a water pump wire – copper. Copper’s suitability is due to its lower resistance to the flow of electrons when compared to aluminum – which has high resistance. Low resistance appreciably reduces voltage drop.

Length of The Run

This is the distance the wire has to cover to reach the power pool pump from the power source, usually a circuit breaker.

You will need thick wires for longer distances (length of the run) and thinner wires for shorter distances.

Why is that so? Thin wires have high resistance to the flow of current. That will lead large voltage drop and eventually, overheating. So, always go for thicker cables if the length of the run is considerably large.

Pump Horsepower and The Voltage

Thicker wires are required for higher values of pump horsepower. (1)

That is because pumps with high horsepower generate more electrical current. So, thinner wires will not be a plausible choice for your pump with high horsepower. As discussed, they have high resistance, and it will be a disaster if you use them for such pumps. Fetch thicker to guarantee the safety of your pool pump.

Also, the voltage transmitted to the pump’s motor affects the choice of wire gauge due to the number of live wires used for 115 and 230 volts.

There is only one hot wire for a 115-volt circuit hence the amperage is supplied solely through the wire. In such a situation, thicker wires are mandatory to curb overheating.

On the other hand, a circuit with 230 volts has two cables supplying voltage to the motor. The amperage gets split evenly. So, thinner wires can be used to power the pump.

Why is Wire Gauge Essential?

The pool pump requires amperage and voltage to generate sufficient power or watts needed to pump water.

Wires are needed to ferry these electrical elements – amperage and voltage. The wire you use must adequately accommodate these electrical elements for your motor to produce the desired amount of watts to function optimally.

If the wires cannot transmit enough voltage and amperage to the pool pump, the motor will strive to attain the optimum wattage.

It can harm itself in the process. Higher amperage generates more heat which stresses and lowers the lifespan of the pump. (2)

The correlation between Power/watts, voltage, and amps is shown in the formula:

| Power (Watts) = Power Factor × Amps × Volts |

Take a look at some of our related articles below.

- How to wire a fuel pump to a toggle switch

- How to hook up 2 amps with 1 power wire

- How to touch live wire without getting shocked

References

(1) horsepower – https://www.techtarget.com/whatis/definition/horsepower-hp

(2) lifespan – https://www.sciencedirect.com/topics/medicine-and-dentistry/lifespan