What is Baling Wires? (Types, Materials, Applications)

From holding together stacks of hay in agricultural fields to bundling up materials in recycling plants, baling wire silently stitches our world together. But what exactly is this wonder wire?”

Baling wire, often called “bale wire” or “haywire,” is commonly used in agriculture. Its primary use? To bind or ‘bale’ materials together – hence the name. Now I know what you might be thinking: “That’s it? Just some plain old wire?” But there’s more to baling wire than meets the eye.

Not just a simple wire, baling wire’s strength, and adaptability have influenced agriculture and waste management globally. Its diverse types and applications showcase its importance in modern industries.

We will talk more about it below.

Discovering the Wonder of Baling Wire

Let’s dive into something that’s been holding things together for ages: baling wire. You might hear folks call it ‘bale wire’ or ‘farm wire’. And sure, it’s a superstar in the agricultural world for bundling up things like hay or straw. But wait, there’s more!

This wonder wire isn’t just about farms. Its versatility stretches into recycling plants and various industries. Imagine it as that sturdy nail or screw in the world of bundling – unseen but oh-so-essential.

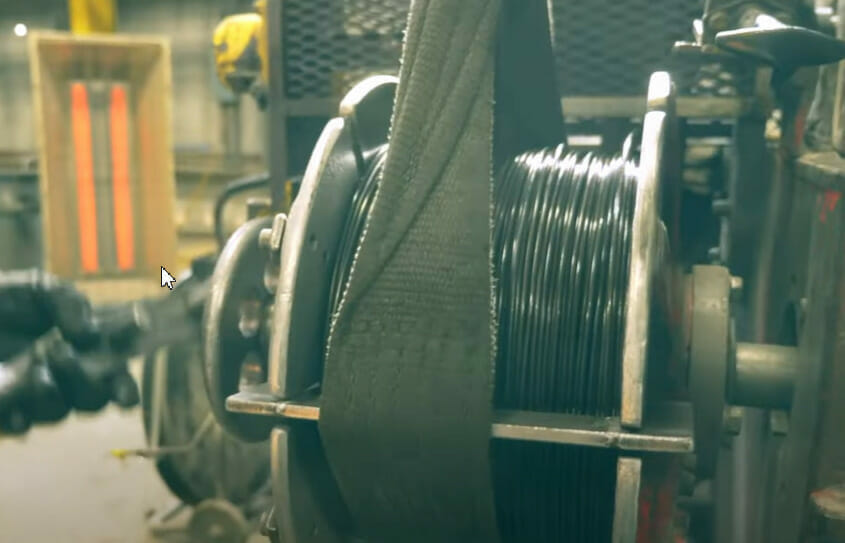

Unveiling Different Types of Baling Wire

Digging into the world of baling wire, it’s clear there’s more to this humble material than first meets the eye. Numerous types are available, each with unique characteristics and applications.

Let me take you on a little tour.

Single Loop Bale Ties

- Description: They’re super flexible and easy to bend, making them a cinch.

- Common Uses: These guys are commonly used in recycling facilities or for packaging materials such as cardboard and paper.

- Benefits: Their adaptability and ease of bending make them convenient for many users.

Black Annealed Wire

- Description: This one’s made from low-carbon steel.

- Common Uses: Typically used in agriculture for tying hay bales.

- Naming Origin: It gets its name from being annealed (heated, then slowly cooled), which gives it some serious strength.

Galvanized High Tensile Wire

- Nickname: Often called ‘farmer’s wire.’

- Features: It’s known for its high tensile strength and corrosion resistance.

- Common Uses: Perfect for outdoor use on farms or vineyards.

Stainless Steel Baling Wire

- Description: Excellent durability against rust and corrosion.

- Common Uses: It shines in marine environments or places with heavy rainfall.

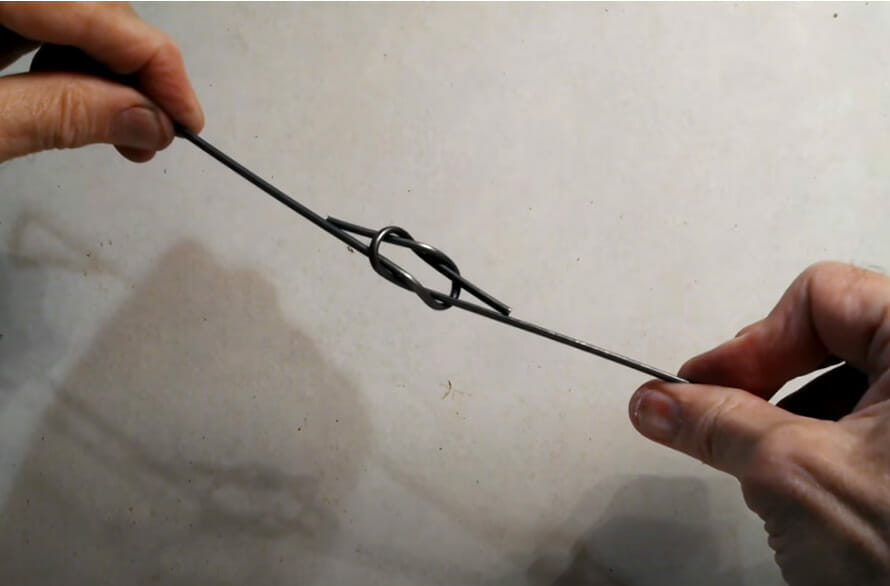

Double Looped End Baling Wire

- Description: Distinguished by the loops on both ends, it is the most versatile baling wire.

- Common Uses: It can be quickly tied without any tools – making it popular across many industries, including construction waste removal and recycling plants.

In a nutshell, here are the types of baling wire and their characteristics and uses:

| Type of Baling Wire | Description/Features | Common Uses |

|---|---|---|

| Single Loop Bale Ties | Super flexible and easy to bend | Used in recycling facilities or for packaging materials such as cardboard and paper |

| Black Annealed Wire | Known for high tensile strength and corrosion resistance, it is often called ‘farmer’s wire.’ | Typically used in agriculture for tying hay bales |

| Galvanized High Tensile Wire | Has loops on both ends, making it versatile | Used outdoors on farms or vineyards |

| Stainless Steel Baling Wire | Distinguished by its durability against rust and corrosion | Used in marine environments or places with heavy rainfall |

| Double Looped End Baling Wire | Has loops on both ends, making it versatile | Popular in construction waste removal and recycling plants |

Diving into the Core: Materials Used

Have you wondered what baling wire is made of? Well, I’m here to break it down for you. It is typically made from a variety of materials. These materials often include steel, iron, and sometimes synthetic materials like polyester.

Steel Baling Wires

- Why It’s Popular: They are quite popular in the agricultural industry because they’re strong, durable, and rust-resistant!

- Varieties & Advantages:

- Galvanized: Provides higher resistance against rust.

- Annealed: Offers superior flexibility.

Iron Baling Wires

- Advantages: Iron is a cheaper option that doesn’t skimp on durability. Though not as widely used as steel, it still gets the job done for less intensive applications.

Other Metals

Manufacturers use other metals like aluminum or copper, though these aren’t quite as common because they’re more expensive and less durable than their counterparts.

Synthetic Baling Twine

- Description: Technically, it is not a wire at all, but it serves the same purpose.

- Materials & Advantages: Made from polyester or other similar materials, this type of twine is lightweight yet impressively strong. Not only that – it’s resistant to weathering and UV rays – making it an ideal choice for outdoor use!

Broadening Horizons: Applications Beyond Agriculture

Beyond the fields and barns, baling wire has carved its niche in various sectors. Its resilience, flexibility, and adaptability have made it an indispensable tool in numerous industries.

- Recycling Centers: Baling wire is widely used to bind materials like paper, cardboard, and certain plastics, making transportation and processing more efficient.

- Construction: It’s common to find baling wire used as a temporary fastener or bundle materials together on construction sites.

- Arts and Crafts: Artists and crafters appreciate baling wire for its malleability. It’s used in sculptures, jewelry, and large-scale art installations.

- Retail: Warehouses and stores use baling wire to keep goods organized and bundled, especially for bulk items.

- Home and Garden: From training plants to grow in a particular direction to mending fences, baling wire is a handy tool for many homeowners.

- Marine Applications: The stainless steel variant of baling wire, known for its rust resistance, is often used in marine environments to fasten or tie materials.

Safety First: Best Practices

Let’s dive into the crucial topic of safety regarding baling wire. You’ve got to get this right because mishandling baling wire isn’t something you want on your resume.

Trust me, these tips can save you a world of hurt.

Personal Protective Equipment (PPE):

- Gloves: Always wear thick gloves when handling baling wire to protect against cuts and scrapes.

- Safety Glasses: To shield eyes from unexpected wire snaps or flying particles.

Proper Storage:

- Store baling wire in a dry, clean place to prevent rust and degradation.

- Ensure it’s coiled or bundled neatly to avoid tangling.

- Store away from walkways or high-traffic areas to prevent tripping hazards.

Safe Handling:

- Unroll or unfold baling wire slowly to avoid sudden releases that can cause injury.

- Never pull tangled wires with force; instead, take the time to untangle them gently.

- Avoid leaving cut ends exposed. They can be sharp and cause injury.

Tools and Equipment:

- Use appropriate tools like wire cutters or pliers for cutting and bending the wire.

- Regularly inspect tools for damage or wear and replace them as necessary.

- Keep tools clean and free of rust or debris.

Workspace Safety:

- Work in well-lit areas to see the wire and your surroundings.

- Ensure the workspace is free of loose wires or off-cuts that could cause trips or falls.

- Keep the workspace organized, placing tools and wires in their designated places after use.

Awareness and Training:

- Be aware of your surroundings, especially when carrying or maneuvering large wire coils.

- Ensure all workers or individuals handling baling wire are adequately trained on safety protocols.

- Refresh training periodically to keep safety guidelines top-of-mind.

Disposal and Recycling:

- Dispose of off-cuts and waste wire in designated containers to prevent floor hazards.

- Consider recycling baling wire, as most types are recyclable. This is both environmentally friendly and can reduce disposal risks.

Emergency Preparedness:

- Always have a first aid kit nearby when working with baling wire.

- Be aware of the nearest emergency exit or safe zone in case of larger accidents or incidents.

Environmental Impact of Baling Wire

Baling wire, in its essence, stands as a beacon of sustainability and adaptability in modern industries. Here’s a closer look at its environmental footprint:

- Recyclability: Most baling wires, especially those made from steel, are 100% recyclable. This reduces the demand for virgin resources, curbing the environmental degradation of mining and raw material extraction.

- Durability and Longevity: Baling wire’s durability means it doesn’t need to be replaced frequently. This leads to less waste over time and reduced resource consumption.

- Waste Reduction in Recycling Centers: Its application in recycling plants cannot be overstated. By bundling recyclable materials like paper and plastics, baling wire ensures efficient transportation, reducing carbon emissions associated with transportation.

- Alternative to Plastics: In many applications, especially in agriculture, baling wire can be an alternative to plastic twines or wraps, which often end up as environmental pollutants.

- Economic Recycling: Given the recyclable nature of steel, reprocessing baling wire can be economically beneficial, further encouraging recycling endeavors.

However, like all materials, baling wire isn’t without its challenges:

- Improper Disposal: If not recycled, baling wire can accumulate in landfills. While it may not release toxins, it still contributes to landfill congestion.

- Resource Consumption in Production: The initial production of baling wire, especially from virgin materials, consumes energy and resources. It’s vital to encourage the use of recycled materials in its production.

Frequently Asked Questions

Q1: Can baling wire be reused?

A1: Yes, if it’s in good condition. However, inspect it for wear, rust, or damage before reusing it.

Q2: Is baling wire environmentally friendly?

A2: Baling wire, especially when made from steel, is recyclable. This makes it preferable over alternatives that might end up in landfills.

Q3: How is baling wire different from regular wire?

A3: Baling wire is designed for strength and flexibility, making it ideal for binding and bundling materials. Its properties might differ from regular wire based on its intended use.

Q4: Are there any alternatives to baling wire in agriculture?

A4: Some farmers use plastic twine or net wraps, especially for baling hay. However, baling wire remains popular due to its durability and strength.

Q5: How do I choose the right type of baling wire for my needs?

A5: It depends on your application. Consider factors like environment (e.g., marine, agricultural), material to be bundled, and desired durability. For instance, stainless steel baling wire might be best if you’re in a coastal area due to its rust resistance.

Q6: Is the baling wire safe to handle?

A6: While the baling wire is sturdy, always exercise caution. Wear gloves and safety glasses, and follow safety guidelines to prevent accidents.

References

Website Resources:

- American Farm Bureau Federation. https://www.fb.org/

- BalerWire.com. https://www.balerwire.com/

- Wire Association International. https://www.wirenet.org/

- The National Association of Manufacturers (NAM). https://www.nam.org/

Video Resources:

PTRBalerAndCompactor

Baler Wire Supply

PA Farms

DILOYA-GROUP

thestraightwire8393

armanitoledo4330

Meirun Hebei

Yao Rocky

Jerry Goggins

D R Baling Wire Manufacturers

staytufffencing

Baling Wire Direct

Gradeall International Ltd