How Many Wires in 3 4 Conduit? (By Conduit Types & Guide)

A conduit is ideal for concealing wires, but you must know how many wires you can fit inside to decide which one to use.

They protect the electrical wires and ensure they last long. But they come in different sizes and have different capacities for holding wires. A ¾” conduit is common, but how many wires can it take?

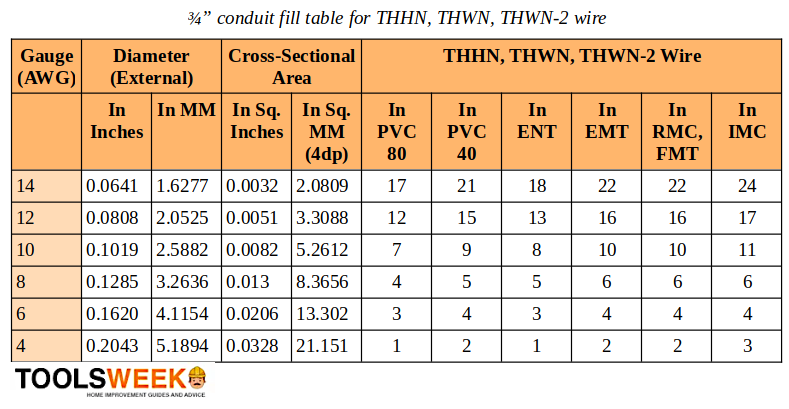

The number of wires you can fit inside a ¾” conduit is usually 12 if they’re all 12 AWG wires or 7 if 10 AWG. The 40% fill ratio for 3 or more wires limits the number to allow proper installation and future additions. But this is for PVC80 conduit, whereas the limit is different for other types, and there are several other factors to consider.

Before putting the wires inside a ¾” conduit, you must consider the other factors. Continue reading to find out.

Procedure

Apply this procedure to work out the maximum number of wires you can fit inside a conduit:

- Step 1: Find the internal cross-sectional area in square inches for the type of conduit you will use.

- Step 2: Multiply by 0.4 (applies to 3 or more wires; see below if fewer).

- Step 3: Look up the external cross-sectional area of the wire type and size you will put inside. We’ll assume they’re all the same.

- Step 4: Divide the result of Step 2 by the result of Step 3. Round down to the nearest whole number (because you can’t have fractional wires).

We’ll detail this procedure to show how to get the information and calculate. It assumes you already have a ¾” conduit and want to know how many wires it can accommodate.

A ¾” Conduit (for Step 1)

A 3 4 conduit is a ¾ (three-quarters of an) inch conduit.

¾” for a conduit is a common size but not the only one. Conduits come in a range of sizes, typically ½”, ¾”, 1”, and 2”. Our focus, however, is on the ¾” conduits.

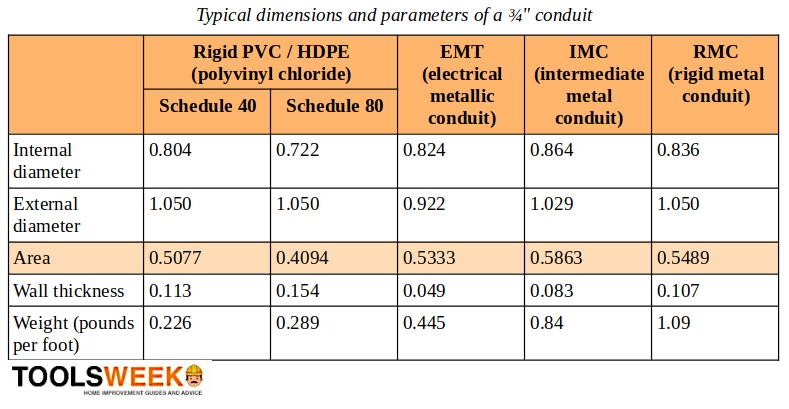

That’s the conduit’s stated diameter, but the actual external diameter is typically 1.05”, and the internal diameter is 0.804” (PVC40) or 0.722” (PVC80). The trade size in millimeters (mm) is 21. The specific typical dimensions and parameters of a ¾” conduit are given in the table below:

The important value in the above table is the internal cross-sectional area (the space inside) because it will determine how many wires you can fit inside, at least theoretically, before making other adjustments.

The internal cross-sectional area is 0.5077” (PVC40), 0.4094” (PVC80), 0.5333” (EMT), 0.5863” (IMC), or 0.5489” (RMC).

Dividing this by the cross-sectional area of each wire (and rounding down) will give the physical limit for the number of wires, but there are more factors to consider.

NEC Code (for Step 2)

The NEC code (300.17) states that the number and size of conductors in a conduit must not prevent heat dissipation or obstruct easy removal of the conductors without damaging them.

Permissible Area and the Fill Ratio

The permissible area is the area allowed to be occupied based on the NEC standard of a 40% fill ratio, which applies to 3 or more nonlead-covered cables installed inside the same conduit.

The fill ratio for a single conductor or cable is 53%, and for 2 is 31%. However, these ratios are subject to more downward adjustments.

Wire Type and Size (for Step 3)

Different types and sizes of wires will affect how many you can fit inside a conduit.

You can only fit so many wires inside a conduit as the space allows. You can get a rough idea of how many wires can fit inside once you know the external cross-sectional area of the exact gauge wire (multiplied by their quantity).

The table below states the number of wires (of type THHN, THWN, and THWN-2 only) you can fit inside six different types of conduits after applying the NEC’s fill ratio restriction (for 3 or more wires inside).

The information was obtained from NEC 2020 tables C.10 and C.11, which specify the maximum number of wires per type of Rigid PVC conduit, schedule 80 and 40, respectively. Type A and EB PVC are covered in subsequent tables C.12 and C.13. The non-PVC conduits covered here are:

- EMT (Electrical Metallic Tubing)

- ENT (Electrical Nonmetallic Tubing)

- FMT (Flexible Metallic Tubing)

- IMC (Intermediate Metal Conduit)

- RMC (Rigid Metal Conduit)

You will have to consult other tables if you want to know about other types of wires, such as the following:

AWG, FEP, FEPB, HF, HFF, KF-1, KFF-1, KF-2, KFF-2, PFA, PFAH, RHH, RHW, RHW-2, SF-1, SFF-1, TFE, THHW, THW, THW-2, THWW, TW, XF, XFF, XHH, XHHW, XHHW-2, Z, ZFF, ZHF, ZW

Other Factors for the Number of Wires in a ¾” Conduit

The number of wires you can fit inside a ¾” conduit is constrained by 4 main factors: diameter, material, insulation, and the fill ratio.

We only considered the diameter, fill ratio, and conductor type above, but several more factors exist. Unless I mention a ¾” conduit, the information applies equally to other size conduits. Other factors include:

- Bends and junctions – Reduce the number of wires inside the ¾” conduit if you have many bends and junctions (or use a larger conduit).

- Conductor – The data above assumes the wires have copper conductors inside. The specifications differ for other types, such as aluminum wire.

- Conduit material – Although I gave data for 6 different conduit types, other types will have different internal space and conduit fill limitations.

- Diameter or area – As you can see from the table, the greater the wire’s diameter or area, the fewer the number of wires you can fit inside the ¾” conduit.

- Fill ratio – The data above assumes you will insert 3 or more wires; otherwise, the fill ratios differ for 1 (53%) or 2 (31%) wires.

- Wire Insulation – A wire’s outer diameter depends on the type of insulation used because different materials have different thicknesses. That’s why I mentioned considering the external cross-sectional area in Step 3 (not the internal area).

- Temperature

- Type and Location

The type of wire and location where you place the conduit also matter, though we didn’t consider them. NEC 342.22-388.22 distinguishes between the following types and locations:

- Audio signal processing

- Class I, II, and III wiring

- Fiberoptics

- Fire alarm circuits

- Fixture wire

- Signs

- Theaters

- Underfloor

Choosing the Right Conduit

Using the right size conduit is important.

If it’s too small, there won’t be enough space, and overcrowding it with wiring increases the risk of overheating and creating a fire hazard. A conduit larger than required is also unsafe and adds unnecessarily to the expense. It might be unable to protect the wires adequately.

References

Website Resources:

- ¾” electrical conduit. https://rohanahardware.com/slon-polycon-3-4-conduit-pipe.html