When Was Aluminum Wire Used? (A Timeline Overview)

The history of electrical wiring takes us back through a captivating timeline of ingenuity and discovery. But among the most interesting chapters is the use of aluminum as a wiring material.

Aluminum wiring emerged as an economical solution during the 1960s and 70s due to soaring copper prices and growing electrical demand in homes. Despite initial success, aluminum’s high thermal expansion rate and oxidation issues led to electrical failures and safety risks

Want to know more interesting facts? Let’s dive right in!

Timeline of Aluminum Wiring Regulation

| Year | |

|---|---|

| Late 1800s to early 1900s | Aluminum building wire was manufactured using utility grade AA-1350 aluminum alloy in sizes small enough for lower load branch circuits in homes due to a housing construction boom in North America and the price of copper spiking. |

| Early 1960s | The first 8000 series electric conductor alloy, still widely used in some applications, was developed and patented by the Aluminum Company of America (Alcoa). |

| Late 1960s | Problems and failures related to branch circuit connections for building wire made with the utility grade AA-1350 alloy aluminum began to surface, leading to a re-evaluation of the use of that alloy for building wire and an identification of the need for newer alloys to produce aluminum building wire. |

| 1972 | The use of single-strand aluminum wiring in home construction declined significantly due to the issues related to the properties of the wire itself, making the installations with aluminum wire much more susceptible to problems. Revised manufacturing standards for both the wire and the devices were developed to reduce the problems. |

| Mid-1970s | The use of single-strand aluminum wiring in home construction declined significantly due to the issues related to the properties of the wire itself, making the installations with aluminum wire much more susceptible to problems. Revised wire and device manufacturing standards were developed to reduce the problems. |

| Late 70s | U.S. Consumer Product Safety Commission (CPSC) issued guidelines on the risks and proper use of aluminum wiring. |

| Present | Aluminum is used in some types of utility wiring and for larger conductors; regular inspection of old wiring is recommended. Aluminum building wiring for modern construction is manufactured with AA-8000 series aluminum alloy as specified by the industry standards such as the National Electrical Code (NEC). |

The Birth of Aluminum Wiring

The dawn of aluminum wiring started around the 1960s and 70s when homebuilding was booming, but copper prices were soaring. Aluminum emerged as a silver (literally) lining.

It was less expensive and seemed to promise similar functionality to copper, making it an attractive option for builders and contractors.

This lighter and cheaper material responded to economic pressures and the increasing demand for electricity in residential homes.

Appliances were becoming common household items, and the amount of power required by the average home began to outstrip previous norms. This new wiring was poised to address this growing demand.

Period of Prominence

Aluminum wiring enjoyed a period of prominence in North America, notably in the United States and Canada, during the mid-1960s to early 1970s.

Builders and homeowners alike warmed up to this new player in the electrical arena. However, as with many new solutions, it was not without its challenges.

Aluminum has a higher rate of thermal expansion compared to copper. This means aluminum wires expand more when electricity passes through them, potentially leading to loose connections.

Despite this, the cost-effectiveness and abundant availability kept aluminum wiring in demand for a while.

Known Issues and Risks

By the mid-1970s, the cracks in the aluminum veneer were starting to show. Reports of electrical failures and even fires in homes wired with aluminum began to surface.

The primary issue is a phenomenon known as “cold creep.” When aluminum wiring heats up (as it does when carrying current), it expands, and when it cools down, it contracts, but it does not return to its original position, a problem not observed with copper.

Further, aluminum oxidizes when exposed to air, creating a layer of aluminum oxide.

This oxide is resistive, unlike the copper oxide that forms on copper wire, causing an increased risk of overheating at the connections.

These issues threatened households’ safety and challenged the use of aluminum as a wiring material. This led to a significant decline in its popularity by the late 70s.

Reaction and Regulation

In reaction to the alarming issues associated with aluminum wiring, the U.S. Consumer Product Safety Commission (CPSC) issued statements and guidelines in the late 70s and early 80s.

These outlined the risks involved with the use of aluminum wiring and recommended inspection and repair options.

As a result, single-strand aluminum wiring in branch circuits, where most of the problems occurred, was no longer used in home construction after the mid-70s.

It’s important to note that aluminum is still used in some types of utility wiring and for larger conductors, where its lightweight properties provide an advantage.

Current Status and Replacement Trends

Today, copper wiring reigns supreme in residential construction, but aluminum wiring can still be found in many homes built during its prominence.

If you live in such a house, don’t panic! Aluminum wiring does not guarantee danger, but it requires proper management.

The Electrical Safety Authority recommends homeowners with aluminum wiring in their homes have a licensed electrician or inspector check the wiring to ensure safety.

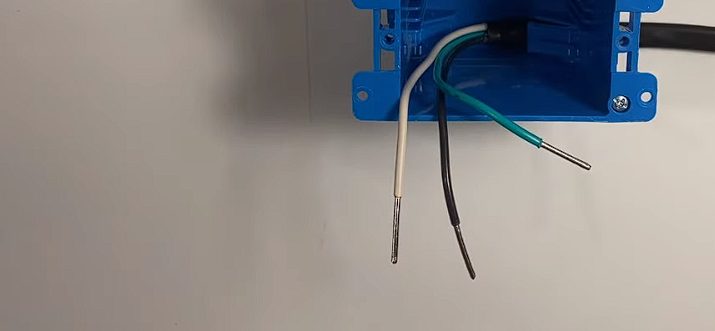

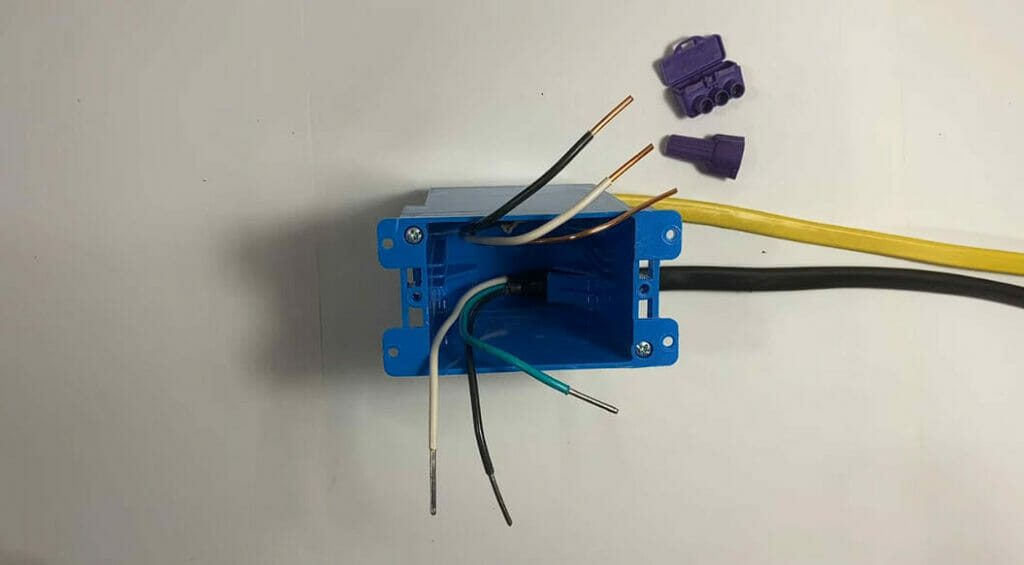

In some cases, complete wiring replacement is recommended, while reconditioning of the connections and junctions is sufficient in others.

References

Organizations:

- Consumer Product Safety Commission (CPSC). https://www.cpsc.gov/

- Electrical Safety Authority (ESA). https://esasafe.com/

Books:

- “Wiring a House: 5th Edition” by Rex Cauldwell

Websites:

- Structure Tech. https://structuretech.com/

Video References

Russian Sparky