What Size Aluminum Wire for 125 Amp Service?

This article will detail what size aluminum wire you need for a 125-amp electrical supply service.

When it comes to wiring for a 125-amp service, the size of the aluminum wire you use is important. Here’s a guide to help you choose the right size. A 125-amp service is a high current level, as used in some homes in the US. Aluminum is used as it is light, flexible, and durable. (1)

For a 125-amp service, you will normally need a 1/0 gauge wire (in AWG), but you may have to take the load, temperature, and distance into account, especially if any of them are high.

Providing a 125-Amp Service

A 125-amp service means the panel can safely carry up to 125 amps of current (but not more).

This total amperage determines the total available capacity you have available in your home. To put it another way, it limits the electricity supply that can be provided and the total power, or wattage, across all the appliances you want to operate at any one time.

To provide this 125-amp service, you might be interested to know what size aluminum wire has been or will be used that connects to your service panel.

Suitable Gauge Values for Different Amperages

You can use the table below to determine which aluminum wire gauge can handle a 125-amp service.

| Amperage | Aluminum Wire Gauge | Copper Wire Gauge |

| 30 | 8 | 10 |

| 60 | 6 | 6 |

| 70 | 4 | 6 |

| 100 | 2 | 4 |

| 125 | 1/0 | 2 |

| 150 | 2/0 | 1/0 |

| 200 | 4/0 | 2/0 |

For a 125-amp service, you will need a 1/0 gauge wire (in AWG).

This will be necessary to use in your home. It can be used in combination with other size wires, but for the 125-amp run, this is the wire size you will need to use.

However, you may need to consider some factors that affect wire size.

Factors that Affect Wire Size

When selecting an appropriate wire size for a 125-amp service, you should consider the load, temperature, and distance.

Load

The load rating is a key factor that affects the required wire size.

The circuit breaker on a circuit can only handle as much as the load rating allows. The higher the load rating, the more it will be able to handle. But the actual gauge size in AWG is smaller than the load rating.

So considering a load, if you anticipate a higher load in the future, you might want to use a thicker gauge wire. This will save you from having to rewire when the load increases.

Temperature

Temperature is another important consideration that affects wire size.

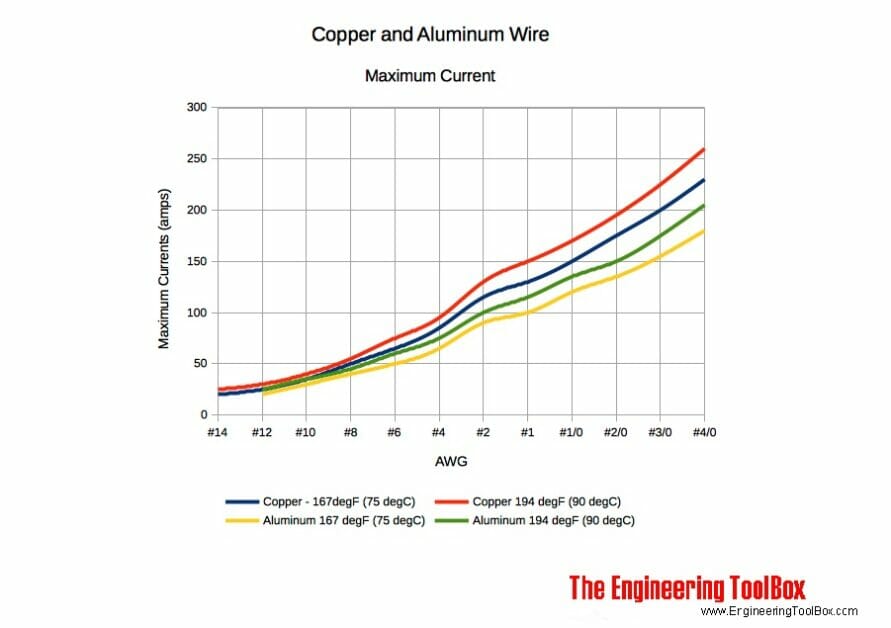

The graph below shows how the AWG requirement and current capacity relate for two different temperatures: 167°F (75°C) and 194°F (90°C). As you can see, the higher temperature (yellow line) requires a slightly thicker gauge than the lower temperature (green line).

If you live in an area with a very high ambient temperature or have heavy machinery that continuously requires a lot of current and power, you may be safer choosing a thicker gauge wire. In this case, you may want to use 2/0 wire instead to be safe.

Distance

The distance or length of the wire determines the voltage drop.

If the voltage drop is significant, which happens when the length of the wire is very long, then a thicker wire is necessary. Roughly, you can expect a 3% voltage drop in a 110V system over a length of around 55 feet.

So, you might need to use thicker gauge wire to cover very long distances.

Advantages of Aluminum Wire over Copper

You might be wondering why we don’t use copper instead of aluminum.

After all, the general wiring inside your home will most likely be copper wire, not aluminum. The reason for considering what aluminum wire you will need is because in this kind of situation, where the current is that high, i.e., 125 amps, aluminum has some advantages:

- Aluminum wiring is lighter than copper wiring (approx. 2x lighter).

- Aluminum wiring is cheaper than copper wiring (approx. 6x cheaper).

- Aluminum is more versatile than copper, which is also easily recycled.

Power Transmission Line Requirements

Cost efficiency is an important consideration for power transmission lines.

Power transmission lines carry electricity over long distances, and the distance between each tower is often hundreds of meters. Although copper can be used for this purpose effectively, aluminum offers two key advantages: it is lighter in weight and cheaper in cost (at the same resistance). Aluminum wire is approximately two times lighter than copper and around six times cheaper.

These advantages make aluminum more suitable for overhead power cables than copper.

References

(1) Carson Dunlop. Principles of home inspection: Systems & standards. Dearborn Real Estate, 2003.

(2) AWG vs. Maximum Current. The Engineering Toolbox. Retrieved from https://www.engineeringtoolbox.com/maximum-current-copper-aluminum-wire-d_1690.html.