What Size Wire for 30 amps 300 Feet?

Using the correct electrical wire size for circuits is crucial to avoiding hazards and preventing fires. This is because voltage drops may occur when energy is sent over a long distance along copper or aluminum wires. Therefore, to guarantee safety, you must use the appropriate wire for your 300 feet circuit.

In general, to wire 30 amps 300 feet, you cannot just use an electrical wire with a 30A capacity; you must use a wire that can handle at least 60 amps. Therefore, utilizing the #6 AWG wire, which can take 65A, is best.

Stick around as I show you some calculations and teach you what cable wire sizes to use for future installations:

How Much Wire Do 30 Amps Need? (80% NEC Code)

You must use a wire that can handle at least 37.5 amps. Thus, the #8 AWG wire, which can hold 50 amps, is the perfect wire for this branch circuit wire.

I usually use a voltage drop calculator or the National Electric Code (NEC) criteria for acceptable 30-amp wire sizing.

**For a 30 amp service, you cannot just use an electrical wire with a 30A capacity.

You should not even use #10 AWG wire with a 35A ampacity. This is because the maximum loading for every branch circuit wire is 80% of the circuit’s ampacity value for any load. (NEC 220-2)

Professionals refer to this as the voltage drop calculator NEC ampacity criterion of 80%. It indicates that those 30 amps must represent no more than 80% of the wire’s ampacity (copper wire or aluminum).

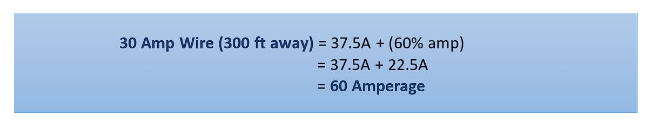

Here is how to determine how much wire with what ampacity you need for a 30-amp electric panel:

Considering the 80 percent NEC requirement, I find the 35A ampacity #10 AWG insufficient. It’s almost big enough with 35A, but not quite.

We require a cable that can handle at least 37.5 amps to use a 30 amp breaker. The size following #10 AWG wire (35A) is #8 AWG wire (50A).

Therefore, the ideal wire size for a 30 amp breaker service is #8 AWG, which has a 50A ampacity.

What Size Wire for 30 Amps 300 Feet Sub Panel?

You will need a wire that can handle at least 60 amps.

Thus, utilizing the #6 AWG wire, which can handle 65A, is the best wire for you.

I will teach you how I calculated it below.

A voltage drop occurs when electricity is transmitted along a 30-amp copper wire or 30-amp aluminum wire over a range. The voltage drop is maintained at less than 3% for distances of less than 10 feet, so you don’t need to consider it. (1, 2)

For instance, you need to consider the voltage drop at 50, 100, 200, or 300 feet. Additionally, you adjust for it by raising the amperage. But, by how much?

According to NEC 310-16, the amps must be increased by 20% for every 100 feet away from the 30-amp sub-panel.

Simply put, this means that you must:

- Raise amps by 10% for 30-amp wire size 50 feet away from the sub panel.

- Raise amps by 20% for 30-amp cable wire sizes 100 feet away from the sub panel.

- Raise amps by 40% for 30-amp wire size 200 feet away from the sub panel.

- Lastly, raise amps by 60% for 30-amp wire size 300 feet away from the sub panel.

The following will show you how to determine the 30-amp power at a distance:

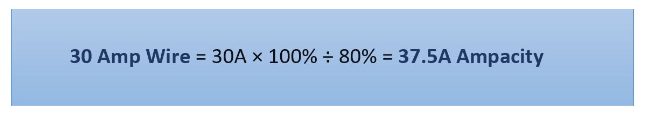

Suppose you want a subpanel 300 feet away from a 30 amp service.

We already know that at a range of 0 feet, you require at least 37.5A of amperage. To solve for the additional 300 feet distance from the sub panel, you must increase the amps by 20% per 100 feet distant. Thus, you must increase 60% amps to be enough for the 300 feet length of your circuit.

Therefore, you require a line that can handle at least 60 amps for a 30 amp service 300 feet away. Unfortunately, the #8 AWG wire’s ampacity is just 50A.

Choose the #6 AWG wire with a 65A ampacity in this situation.

Take a look at some of our related articles below.

- What size wire for 30 amps 200 feet

- What size wire for 150 amp service

- Where to find thick copper wire for scrap

References

(1) electricity – https://www.eia.gov/energyexplained/electricity/

(2) copper – https://www.livescience.com/29377-copper.html