What is SIMpull Wire? (Unraveling its Benefits and Uses)

Have you ever had a home renovation project that required electrical wiring? If so, you’ve likely stumbled across SIMpull wire. It’s a game-changer in the world of electricians and DIY enthusiasts alike.

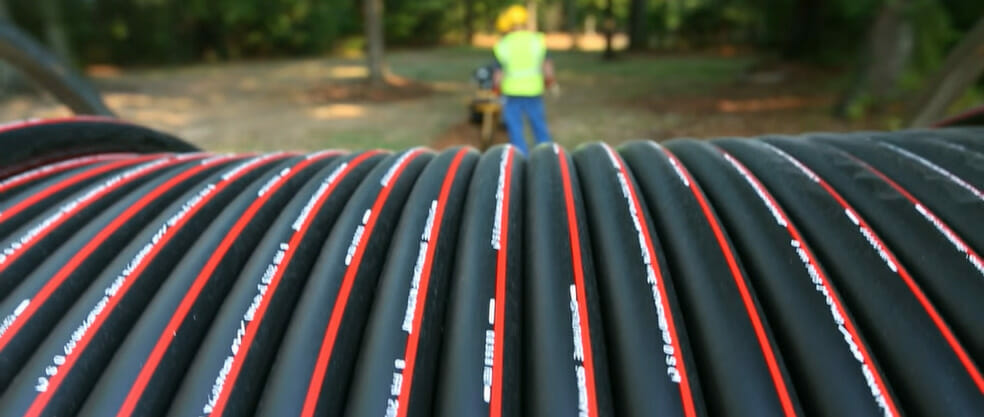

SIMpull wire is a revolutionary alternative to traditional electrical wires, offering increased flexibility and user-friendliness. Developed by Southwire, this innovation stems from years of research and is designed to glide through conduits without lubrication.

Its unique features, including the NoLube technology, reduce installation time by 50% and negate the need for traditional pulling lubricants. SIMpull wire is durable, safe, versatile, and available in various sizes and colors for residential and commercial use. Once you experience SIMpull, there’s no going back.

Let’s explore further below.

History and Development of SIMpull Technology

Diving into the annals of history, we’ll find that Southwire’s SIMpull technology isn’t just a spur-of-the-moment invention. It’s rooted in years of dedicated research, ground-breaking innovation, and an unwavering commitment to improving electrical wire installation.

- 2009: The birth of revolutionary SIMpull technology.

- Southwire is a leading manufacturer in the cable industry.

- Primary goal: to make lives easier for electricians. They aimed to reduce physical strain and increase productivity on job sites.

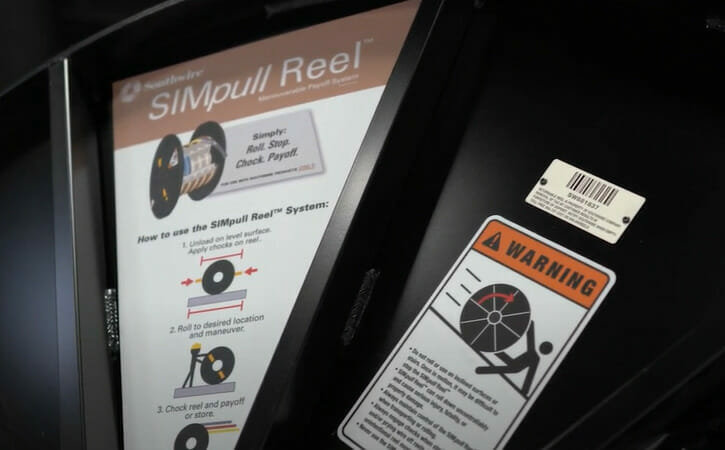

- Introduction of SIMpull: A solution abbreviated from ‘Simultaneous Inner Member Pull’.

- Unique features: using advanced cable geometry design and enhanced lubrication solutions.

- The outcome? A friction-reducing system that allowed wires to glide through conduit effortlessly.

- 2010: Introduction of the SIMpull Head.

- This is a pre-installed pulling grip, which further eases wire installations.

- 2012: Launch of the SIMpull CoilPAK™.

- A package designed for increased maneuverability and safer handling.

- 2015: Release of the groundbreaking SIMpull Flange.

- An add-on tool designed to transform how wire drums are transported and pulled.

Features of SIMpull Wire

When it comes to quality and efficiency, nothing beats SIMpull wire. It’s a revolutionary product that has transformed the electrical industry. But what makes it so special? Let’s dive in.

| Feature | Description |

| Unique Design | Features exclusive NoLube technology. Eliminates the need for traditional pulling lubricants.Reduces installation time by 50%. |

| Durability | Robust jacket shields against damage. Suitable for extreme conditions. |

| Safety Commitment | Design reduces the chances of accidents. Lowers exposure to chemicals. |

| Versatility | Available in diverse sizes and colors. It is Ideal for both residential and commercial projects. |

| Coil Packaging | Distinctive coil packaging ensures a smooth payout. Avoids twists and tangles. |

Benefits of Using SIMpull Wire

I’ve been in the electrical industry for quite a while, and I’ve seen firsthand how technology can simplify tasks and improve efficiency. I’m excited to discuss the benefits of using SIMpull wire – a game-changer in electrical wiring.

| Benefit | Description |

| Time-saving | Pulling this wire through conduits is much easier compared to traditional cables. This ease of installation reduces labor hours, saving time and money. |

| Safety | Its smooth surface greatly reduces the risk of injuries like cuts and scrapes, making it safer for workers. |

| Reliability | Made with durable design and high-quality materials, ensuring longevity and dependability. |

| Ease of Identification | Color-coded jackets identify different wire types easily, even under low light conditions. |

| Versatility | It is available in various sizes for small residential jobs and large commercial projects. |

Common Applications

Diving right in, let’s talk about the common applications of SIMpull wire. This marvel of modern engineering isn’t just for show – it’s got many practical uses that might surprise you.

- Residential Housing

- It’s commonly used to streamline electrical work and make new home construction or renovations much more efficient.

- The slip technology incorporated into SIMpull wire eases installation, meaning electricians can save time, and homeowners can save money.

- Commercial Settings

- Companies large and small are turning to this innovative product to simplify their wiring needs.

- Large office buildings, retail locations, and even factories benefit from the efficiency that SIMpull wire brings.

- Public Infrastructure Projects

- SIMpull wire is utilized in various public infrastructure projects.

- From schools and hospitals to airports and train stations, this versatile product is helping our communities function better daily.

- Special Projects

- Entertainment venues and sports stadiums, known for their complex wiring systems, often turn to SIMpull wire.

- In these scenarios, getting wires installed quickly and correctly is crucial, making SIMpull wire an ideal choice!

Comparative Analysis

Let’s dive right into the heart of the matter – SIMpull wire. It’s an innovative solution in the electrical wiring world, offering many benefits that traditional wires can’t match.

Here’s a quick rundown:

| Feature | SIMpull Wire | Traditional Wire |

| Ease of Installation | High | Moderate-Low |

| Heat Resistance | High | Moderate |

| Durability | High | Varies |

| Environmental Impact | Low-Moderate (Recyclable) | High (Non-Recyclable) |

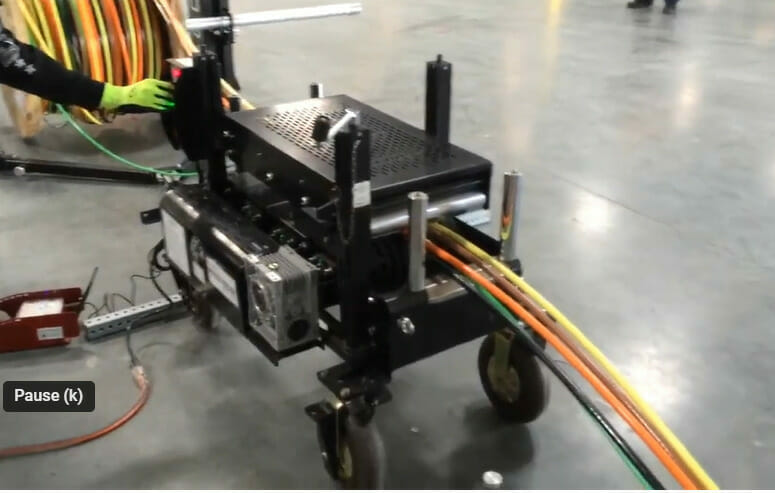

How to Use SIMpull Wire

Plan Ahead: Before starting, map out your wiring route. Measure the lengths needed to avoid excess waste and ensure you have enough wire for the project.

Cutting: When cutting the wire, use the appropriate wire cutters for the gauge you’re working with. Ensure a clean cut without fraying the ends.

Installation: Feed the SIMpull wire into the conduit or designated pathway. Given its design, you’ll find it glides smoothly without much resistance. Ensure the pathway is free of obstructions for an even smoother process.

No Lubrication Required: Unlike traditional wires, SIMpull doesn’t require additional lubrication, simplifying the pulling process.

Connection: Once you’ve run the wire to its destination, strip the insulation at the ends using a wire stripper. Make sure to connect the wire securely to terminals or connectors.

Economic Analysis

Understanding the cost implications in electrical installations is as vital as assessing the technical advantages.

Let’s dissect the numbers and see if SIMpull Wire offers an economic edge.

| Economic Factor | SIMpull Wire | Traditional Wire |

|---|---|---|

| Initial Cost | Moderately High | Lower |

| Installation Cost | Lower (due to reduced installation time) | Higher |

| Maintenance Cost | Low (durable design) | Moderate to High |

| Operational Efficiency | High (ease of use, no lubricants needed) | Moderate |

| Lifespan & Durability | Longer (higher quality materials) | Shorter to Moderate |

| Replacement Frequency | Less Frequent | More Frequent |

| Recycling/Disposal Costs | Lower (recyclable) | Higher (often non-recyclable) |

| Productivity Benefits | High (quicker installations) | Moderate |

| Training/Onboarding Costs | Moderate (some new training may be required) | Lower (more standard) |

| Total Economic Impact | More Economically Efficient in the Long Run | May be Costlier Over Time |

Safety Protocols

When working with SIMpull wire, I can’t stress enough the importance of safety. It’s not just about getting the job done but ensuring you’re doing it in a way that keeps you safe.

This is why understanding safety protocols is crucial.

- Use Protective Gear

- Gloves, safety glasses, and sturdy footwear can make a difference when handling SIMpull wire.

- They protect against potential injuries from sharp wire ends or any accidental contact with electricity.

- Proper Storage

- SIMpull wires should always be stored in a clean, dry place to prevent deterioration or damage.

- Moisture can cause corrosion over time, while dust can affect its electrical conductivity.

- Handle with Care

- Avoid pulling or bending them excessively.

- It could lead to internal damage, which isn’t visible externally but may affect their performance.

- Regular Inspections

- Inspection for any signs of wear or damage before use.

- If there’s even a slight doubt about the integrity of the wire, it’s safer to replace it than risk an accident.

- Safety First

- Working with electricity isn’t something you should take lightly.

- If you’re not trained for it, don’t try to DIY electrical installations or repairs involving SIMpull wires!

Additional Safety Tips for Using SIMpull Wire

While adhering to established safety protocols is paramount when working with SIMpull wire, there are always extra precautions and insights that can elevate your safety practices.

We delve into supplemental safety tips, shedding light on lesser-known advice and expert recommendations to ensure an even safer and more efficient experience with SIMpull wire.

Stay Informed: Before starting any electrical work, always check for any new or updated safety guidelines related to SIMpull wire.

Turn Off Electricity: When working with wiring, ensure the power source is turned off to prevent accidental shocks or electrical incidents.

Check Wire Integrity: Before installation, visually inspect the wire. Any nicks, cuts, or other damages can compromise its safety and effectiveness.

Keep Work Area Dry: Water and electricity don’t mix. Always ensure your work area is dry to prevent any accidental electrocutions.

Avoid Mixing Wires: If a project involves SIMpull and traditional wires, clearly segregate and label them. This will ensure you apply the right techniques and precautions for each type.

Frequently Asked Questions

1. Is SIMpull Wire more expensive than traditional wire?

Answer: Prices can vary depending on specific product lines, quantities, and your purchasing region. It’s always best to consult with suppliers for current pricing.

2. Can SIMpull Wire be used outdoors?

Answer: While SIMpull Wire is designed for durability, it’s essential to check the specifications of the particular product variant for outdoor suitability and exposure to environmental elements.

3. How is SIMpull Wire’s environmental impact measured?

Answer: SIMpull Wire is recyclable, reducing its environmental footprint. The exact environmental impact would depend on production processes, materials used, and recycling efficiency.

4. Is there a warranty on SIMpull Wire products?

Answer: Warranty details might vary based on the manufacturer and specific product line. It’s advisable to check with the manufacturer or distributor for warranty specifics.

5. Are there any situations where traditional wires are preferred over SIMpull Wires?

Answer: While SIMpull Wire offers many advantages, specific applications or conditions might be where a particular type of traditional wire is preferred. Consulting with an electrical expert can provide clarity.

6. Do I need special tools or equipment to install the SIMpull Wire?

Answer: Generally, SIMpull Wire is designed for ease of use and can be installed using standard electrical tools. However, specific installations might benefit from dedicated tools offered by the manufacturer.

7. How long has Southwire been in the cable manufacturing industry?

Answer: Southwire has been a leader in the cable industry for many years. For specific details on their history and duration in the industry, it’s best to consult directly with the company or visit their official website.

8. Are training or certification programs available for SIMpull Wire professionals?

Answer: Some manufacturers and industry organizations offer training and certification programs for new products and technologies. It’s worth checking with Southwire or related entities for available training options on SIMpull Wire.

9. Can SIMpull Wire be custom-ordered in specific lengths or configurations?

Answer: Manufacturers like Southwire might offer custom order options based on bulk requirements or specific project needs. Direct communication with the supplier or distributor would provide the most accurate information.

10. How does SIMpull Wire handle high-voltage applications?

Answer: SIMpull Wire is designed for robustness and safety, but it’s crucial to check the specifications and ratings for each wire type to ensure it matches the application’s voltage requirements.

References

Website Resources:

- Southwire Company. https://www.southwire.com/

- National Electrical Contractors Association (NECA). https://www.necanet.org/

- National Electrical Manufacturers Association (NEMA). https://www.nema.org/

- Electrician Talk. https://www.electriciantalk.com/

Video Resources:

Southwire