What is Romex Wire? (Types and Features)

As someone who’s spent the better part of 15 years knee-deep in wires, I’ve found Romex to be a constant companion – if you’re messing with wires, it’s high time we chat about this reliable old friend.

Key Takeaways – Romex wire, a brand by Southwire, revolutionized home electrification with its safe, affordable, and easy-to-install design. Composed of color-coded copper conductors, each coated with PVC insulation and housed in a non-metallic sheath, Romex caters to various needs.

Let’s take a closer look at Romex wire!

Origins of Romex Wire

The term ‘Romex’ has an interesting origin story. It’s a brand name, much like Kleenex or Xerox, which has become a generic term for the product itself.

The name ‘Romex’ is owned by Southwire, an American manufacturer of wire and cable. It’s been around since the early 20th century and has cemented itself as a household name.

Romex wire is a product of the evolution of electrical wiring. It was developed to be safer and easier than previous options like knob-and-tube or metal conduit wiring.

The goal was simple: create a wire that could carry electricity efficiently and safely while being durable and easy to install.

By achieving this, Romex wire played a huge role in the electrification of homes across America.

Its affordability and ease of use allowed more homes to have electric power, shaping the modern comforts we enjoy today.

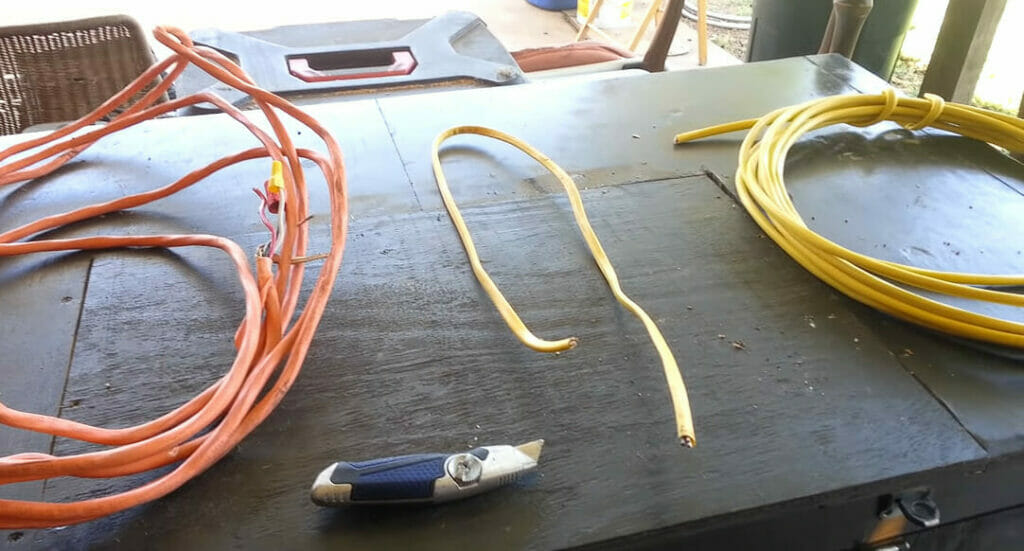

Components and Structure of Romex Wire

Peel back the outer jacket of a Romex wire, and you’ll find a simple but effective design.

At its core, Romex wire comprises multiple conductors, each individually insulated, and an overall non-metallic sheath.

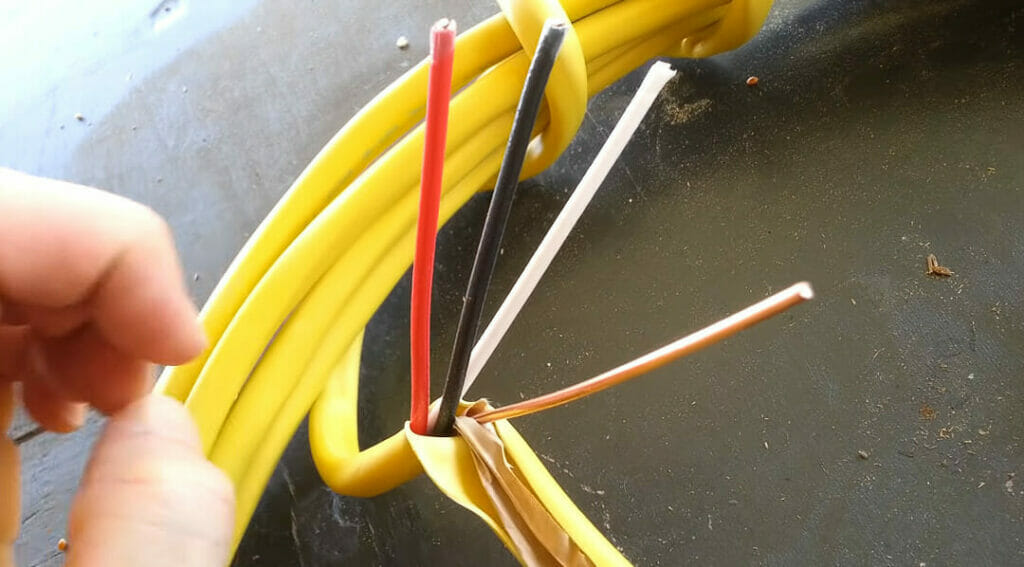

First off, the conductors. These are typically made from copper, renowned for its excellent conductivity.

Each conductor is color-coded: black and red for hot, white for neutral, and bare or green for ground. Simple, right?

Next, the insulation. Each conductor is coated with a layer of PVC insulation.

This barrier prevents electricity from escaping the conductor and causing a short circuit. It also shields the conductors from physical damage.

Finally, the sheathing. All the conductors are wrapped in a non-metallic, usually vinyl, sheath. This extra layer of protection keeps everything bundled together and protects against environmental damage.

Types of Romex Wire

Much like a well-stocked toolbox, Romex wire presents various options, each catering to distinct electrical needs.

The wire is classified based on its gauge (indicating thickness) and the number of conductors it contains.

A useful fact to remember is that the lower the gauge number, the thicker the wire, and the greater its capacity to carry current.

To break it down further, here are some common types of Romex wire:

- 14/2 Wire: This is suited for 15-amp circuits. It’s commonly used for light fixtures and general-purpose outlets in residential properties. This type typically powers items like computers, lamps, and radios.

- 12/2 Wire: Designed for 20-amp circuits, it’s ideal for household kitchen and laundry rooms, powering devices such as microwaves, refrigerators, and washing machines.

- 10/2 Wire: This type is suitable for 30-amp circuits, and it’s often used for large appliances such as electric water heaters and dryers.

- 10/3 Wire: This thicker wire is designed for larger appliances that require a dedicated circuit, like an electric range, air conditioners, or a sub-panel.

Interpreting the labeling on Romex wire is simpler than it may appear at first glance.

For example, the ‘NM-B’ label denotes ‘Non-Metallic type B,’ the ‘B’ signifying that the wire is heat-rated up to 90 degrees Celsius, making it suitable for most residential applications.

Each Romex wire type is crafted to serve a unique purpose, from powering simple light fixtures to energizing heavy-duty appliances. Having the right wire for the job isn’t just about efficiency—it’s a safety necessity.

As always, when dealing with electrical tasks, ensure you’re equipped with the appropriate knowledge or hire a professional to handle the job.

Romex Wiring vs. Other Types of Wires

Here’s a comparison between Romex wire, knob-and-tube wiring, and metal conduit wiring:

| Factor | Romex Wire | Knob-and-Tube Wiring | Metal Conduit Wiring |

|---|---|---|---|

| Ease of Installation | High | Low | Medium |

| Cost | Low | High | High |

| Safety | High | Medium to Low | High |

| Durability | High | Medium | Very High |

| Flexibility in Wiring Layouts | High | Low | Medium to High |

| Grounding | Available | Not Available | Available |

| Insulation | High | Low | Depends on Wire Used |

- Ease of Installation: Romex wire is flexible and relatively easy to pull through walls and ceilings, making it easier to install than the other two. Knob-and-tube wiring requires skilled labor and careful installation, making it less easy to install. Metal conduit wiring requires bending and cutting the conduit, which can be labor-intensive.

- Cost: Romex wire tends to be cheaper than knob-and-tube and metal conduit wiring. The latter two require more labor for installation, driving up costs.

- Safety: Romex wire is safer than knob-and-tube wiring because it comes with a ground wire, which helps prevent electrical shocks. Romex and metal conduit wiring are generally safer than knob-and-tube, an older system that can pose safety risks if it’s not well maintained.

- Durability: While Romex wire is durable, metal conduit wiring is the most durable because the metal conduit protects the wires from damage. However, knob-and-tube wiring, being older technology, tends to be less durable than the other two.

- Flexibility in Wiring Layouts: Romex wire allows more flexibility in wiring layouts than knob-and-tube. Metal conduits can also offer flexibility, although changing layouts can be more labor-intensive due to the need to bend and cut the conduit.

- Grounding: Romex wire and metal conduit wiring allow for grounding, which helps prevent electrical shocks. Knob-and-tube wiring does not include a ground wire.

- Insulation: Romex wire has better insulation than knob-and-tube, which can help prevent electrical shorts and fires. The insulation in metal conduit wiring depends on the type of wire used within the conduit.

Common Uses of Romex Wire

Romex wire is the Swiss Army knife in the realm of residential wiring. With its flexibility, it covers an extensive range of applications.

It’s not just about powering lights or devices; it’s about making our homes functional and our lives comfortable.

Here are some of the common uses of Romex wire:

| Circuit Type | Description | Typical Romex Wire Type |

|---|---|---|

| Lighting Circuits | Used to power lighting circuits in residential settings, from bedside lamps to kitchen lights. | 14/2 |

| Outlet Circuits | Commonly used for outlet circuits, delivering power to everyday devices and appliances like phones and desktop computers. | 12/2 |

| Appliance Circuits | Used for major appliances like dryers, ranges, or air conditioners that require more power. | 10/2 or 10/3 |

| Renovation Projects | A favorite for remodeling or additions to existing structures due to its ease of use, installation, and reliability. | Depends on the specific power needs of the project |

While Romex wire is typically concealed within walls, ceilings, or floors in residential properties, it finds uses beyond homes too.

It’s utilized in some commercial and light industrial settings, providing electrical solutions on a larger scale. However, remember that Romex wire isn’t suitable for exposed or outdoor applications.

It needs protection from physical harm and environmental elements to function effectively and safely. Always consider the specific requirements of your project when selecting wiring solutions.

Regulations and Code Compliance for Romex Wire

The use of Romex wire is stringently regulated by a comprehensive set of rules, primarily outlined by the National Electrical Code (NEC).

This body sets safety standards for electrical wiring across the United States, ensuring that our homes and buildings are electrically sound and safe.

The NEC is intricate when it comes to Romex wire. It provides specific directives on which types of Romex wire are appropriate for different applications.

For example, it stipulates the usage of 14/2 Romex wire for 15-amp circuits, while 12/2 and 10/2 are specified for 20-amp and 30-amp circuits, respectively.

Moreover, the NEC outlines correct installation procedures. It addresses everything from securing the wire properly to maintaining a safe distance from hot surfaces or where physical damage might occur.

Following the NEC’s installation guidelines ensures the electrical system operates optimally and minimizes risks of electrical fires or shocks.

In addition to the NEC, local building codes have a say on Romex wire usage. These codes vary by locality, and some areas may impose additional restrictions or requirements.

It could range from stringent rules on wire burying depth for underground applications to the type of wire suitable for certain building structures.

Failing to comply with these regulations doesn’t just carry legal consequences; it can create serious safety hazards.

Improper use or installation of Romex wire can lead to electrical failures, fires, or shocks.

As such, whether you’re a DIY enthusiast or a professional electrician, it’s paramount to stay updated with the NEC and local building code requirements to ensure safe and compliant electrical practices.

References

Organizations:

- NFPA: National Electrical Code (NEC). https://www.nfpa.org/codes-and-standards/

Books:

- Black & Decker The Complete Guide to Wiring, Updated 7th Edition

Websites:

- The Spruce. https://www.thespruce.com/

- Wire & Cable Your Way. https://www.wireandcableyourway.com/

Video References

S33 Electrical

Phillip Bridges