What is AWG? (A Simplified Guide)

Understanding AWG is crucial whether you’re an electrical engineer, a DIY enthusiast, or just a curious homeowner wanting to learn more about the systems that make your house tick.

AWG, or American Wire Gauge, is a standardized system for determining wire diameters primarily used in North America. The system helps determine the maximum current a wire can handle safely, which is important in various industries, such as residential wiring, electronics, and automotive systems.

In this article. I’ll guide you through the ins and outs of AWG, detailing its history, how it works, and why it matters.

American Wire Gauge (AWG)

Definition of AWG

The American Wire Gauge (AWG), the Brown & Sharpe wire gauge, is a standardized wire gauge system used predominantly in North America for the diameters of round, solid, nonferrous, electrically conducting wire.

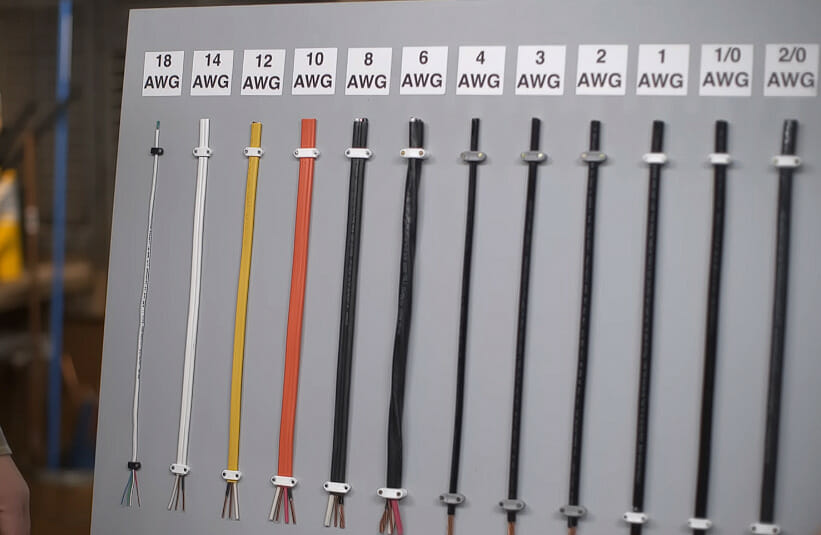

The increasing AWG number corresponds to a decreasing wire diameter or cross-sectional area. AWG measures various wire types, including electrical wiring, electronic cable, and industrial and aircraft conductors.

History and Development of AWG

The AWG system was developed in the mid-19th century to standardize wire diameter and reduce confusion among manufacturers and consumers.

Before AWG, each wire industry or manufacturer often had its unique system for measuring wire sizes.

The AWG system was introduced by Brown & Sharpe, a leading industrial tool company, to standardize these measurements and has been widely accepted and utilized in North America since then.

The AWG system was initially formulated based on the steps of wire drawing technology available at its inception. The system was made official and was broadly recognized in 1857.

Over the years, it has been improved to accommodate the development of technology and the needs of industries.

Although there have been attempts to replace it with a more metric-based system, AWG remains the standard for wire measurement in North America.

How AWG System Works

In the AWG system, the diameter of a wire is defined by a simple mathematical formula: the diameter in inches is 0.005 times 92, raised to the power of 36 minus the gauge number, divided by 39.

This results in a geometric progression, with each successive AWG number representing a decrease in diameter of approximately 10.5%.

The gauge numbers typically range from 0000 (4/0) to 40. A lower gauge number signifies a thicker wire, while a higher one signifies a thinner wire.

For instance, a 0000 AWG wire will have a diameter of 0.46 inches, while a 40 AWG wire will have a diameter of only 0.0031 inches.

This AWG system is extremely useful when working with electrical wiring as it aids in determining the maximum current a wire can handle without overheating, which could potentially lead to fires.

It’s important to note that in the AWG system, physical properties, such as wire diameter, electrical resistance, weight per unit length, etc., can be estimated based on the AWG number, assuming the wire is made of a certain material (typically copper).

Role of AWG in Electrical Conductivity

Relationship Between AWG and Electrical Conductivity

The American Wire Gauge (AWG) system plays a significant role in determining the electrical conductivity of a wire.

Electrical conductivity measures how well an electric current can pass through a certain material.

As the wire size (diameter) decreases in AWG, the AWG number increases, and the electrical conductivity decreases.

This decrease in conductivity is due to the increase in resistance that comes with smaller wire diameters.

Smaller wires have a smaller cross-sectional area for the current to flow through, which causes an increase in resistance, leading to lower conductivity.

Effect of Wire Diameter on Resistance and Current Carrying Capacity

The wire diameter, defined by the AWG size, directly affects a wire’s resistance and current-carrying capacity.

Resistance measures how much a wire opposes the flow of electric current.

It is inversely proportional to the cross-sectional area of the wire – as the wire diameter decreases (or as the AWG number increases), the resistance increases.

This is because there is less area for the current to flow through, which increases opposition to the flow of electrons.

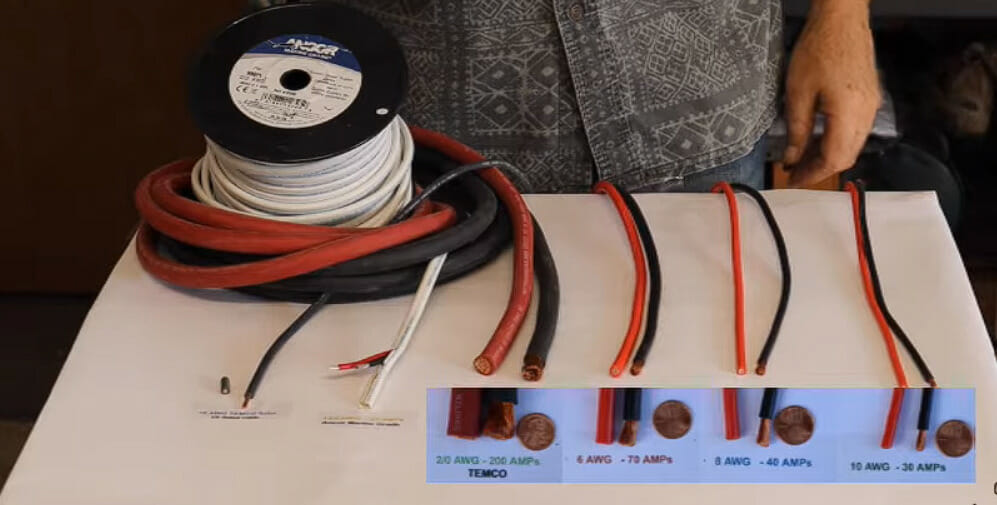

A wire’s current-carrying capacity (or ampacity) is the maximum amount of electric current the wire can safely carry without overheating or causing a fire risk.

The current-carrying capacity is directly proportional to the wire’s cross-sectional area (or inversely proportional to the AWG number).

Thus, as the wire diameter increases (or as the AWG number decreases), the wire’s current-carrying capacity also increases.

Real-world Applications and Examples

The AWG system is used extensively in various industries and applications, including residential and commercial wiring, automotive systems, electronics, and more.

For example, a 14 AWG wire is typically used for lighting circuits in residential wiring. A larger 12 AWG wire is often used for outlets that may handle larger electrical loads.

For major appliances like electric ranges, air conditioners, or clothes dryers, even larger wires such as 10, 8, or 6 AWG may accommodate the high current demand.

Understanding AWG is crucial when designing and manufacturing electronic devices in the electronics industry.

For example, the internal wiring of a device may require very thin wires (high AWG number) due to space constraints, but this must be balanced against the device’s power requirements to ensure the thin wires can carry the necessary current without overheating.

In the automotive industry, the AWG system helps engineers select the appropriate wire size for various components in a vehicle’s electrical system, such as the battery cables, starter motor cables, and the wiring for lights and accessories, all of which may have different current requirements.

Basic AWG Guide for Common Applications

| AWG Size | Diameter (in inches) | Typical Application |

|---|---|---|

| 0000 | 0.46 | Utility power cables |

| 0 | 0.325 | Welding cable, battery cable |

| 4 | 0.204 | Battery cables in cars |

| 6 | 0.162 | High-power electric devices |

| 8 | 0.128 | Amplifiers, electrical panels |

| 10 | 0.1019 | Electric clothes dryers |

| 12 | 0.0808 | Household outlets |

| 14 | 0.0641 | Lighting circuits |

| 20 | 0.0320 | Internal appliance wiring |

| 24 | 0.0201 | Electronics, control circuits |

| 30 | 0.0100 | Small electronic devices |

| 40 | 0.0031 | Very thin electronic devices |

This table provides a general guide. Still, always consult professional advice when dealing with electrical systems.

References

Organizations:

- The National Electrical Manufacturers Association (NEMA). https://www.nema.org/

- The Institute of Electrical and Electronics Engineers (IEEE). https://www.ieee.org/

Books:

- “Electrical Wiring Residential” by Ray C. Mullin and Phil Simmons.

- “American Electricians’ Handbook, Sixteenth Edition” by Terrell Croft, Wilford Summers

Video References

This Old House

Frugal Factor