What Size Breaker for a Well Pump? (Recommendations & Calculations)

If you’re trying to find out what size circuit breaker to use for your well pump, this article is for you.

As a general example, assuming it will be used in a 120 V system, a 1 HP pump may need a 15-20 A breaker, and a 2 HP pump may need a 25-30 A one.

To know exactly which size breaker you must use for a well pump, you should check the manufacturer’s specification in the manual first for the particular model you have. The same information, but more generally applicable, can also be found in your local code requirements. Otherwise, calculate the size yourself, or consult an electrician.

I’ve detailed all you need to know to help you use the right circuit breaker below.

Well Pumps

A well pump may be either a jet type if it is shallow or a submersible pump if the water depth is at least 25 feet. Only use a submersible type if it is completely covered in the water.

The submersible type is usually more efficient, requiring less power and drawing less current compared to above-ground-level pumps. The suggested circuit breaker values assume you are using a submersible pump.

Why the Right Size Breaker is Important

Unlike standard motors, submersible pumps especially, especially well pumps, need special protection from overload.

It is important to use the right size circuit breaker for your well pump because if it is too small, it will have a thinner wire than needed, which can catch fire when used with a powerful pump. It will also trip too frequently. If it is too large, it will have a thicker wire than needed, which may fail to provide the safety for which circuit breakers are designed.

The right size breaker can protect the motor from overheating from dangerous current overload levels and burning up. [2]

You can get this information about which size to use from the well pump manual by consulting your local code, calculating it yourself, or asking an electrician.

Consulting the Well Pump Manual

The manufacturer’s specification should be consulted first, if possible because it takes into account all the essential details for that particular well pump.

This includes the type of connection (single or three-phase), distance, temperature, initial current, the likely voltage drop, and official code requirements. Professional pump installers always look for this specification, which you will find in the well pump’s manual.

The manual typically gives detailed instructions on the most suitable sized breaker to use and also the right type and size of wire, for the specific well pump model.

This information, including the current, may be stated on the pump itself. In the above example, the water pump operates at around 10 A, with a maximum load of under 15 A. This case may require a 15 or 20 A circuit breaker.

A Few Examples

To give some examples, the table below shows what amperage circuit breaker you might be expected to use for a single-phase 220V electricity connection. It is only a general guide; you will still need to consult your manual.

| Connection Type (phase) | Horse-Power (electric HP) | Voltage (V) | Circuit Breaker (amperage) |

| Single | 0.75 HP | 120 V | 15 amps |

| Single | 1 HP | 120 V | 15 amps |

| Single | 1.5 HP | 120 V | 20 amps |

| Single | 2 HP | 120 V | 25 amps |

Note that the above table assumes a voltage drop within the range ±5% (see further below) and does not consider the distance. The following things must be considered in general:

- The type of connection is either single-phase, as in normal domestic supply, or three-phase.

- Distance – Generally, a lower gauge (thicker) wire is needed to cover a longer distance or for a higher current if the pump uses a powerful motor. If the distance is within 200 feet, you may need a 14 gauge copper wire, and if it’s longer but within 300 feet, then a 12 gauge one.

- Horsepower – It usually ranges between 0.5 HP and 2 HP, but maybe as high as 3-5 HP if it has a more powerful motor.

- Temperature – Ambient temperature in which the pump will be used.

- Voltage supply – The 110-120 V used in North America, lower than the European standard of 220-240V, produces higher amps.

- Type of pump – Submersible pumps usually use fewer amps than above-ground pumps because they operate more efficiently.

- Official code requirements – See the section on consulting the local code.

Consulting the Local Code

The same information about what circuit breaker to use for your well pump can also be found in your local code requirements. However, it would be more generally applicable than specific to your model.

You might want to consult the local code instead of looking in the manual if it is unavailable or doesn’t give clear information. In these cases, the local code requirements are the best alternative source to know which circuit breaker to use.

It should be safe to use its recommendation because local codes usually state the highest breakers by considering the maximum likely current. For this reason, it may be possible to use a smaller one, but try to use the recommended sized breaker.

If you cannot find the local code, consult an electrician or calculate the right-sized breaker yourself.

Calculating the Right-Sized Breaker

Another option to consulting the manual or local code is calculating the circuit breaker size you will need for your well-pump.

To do this, you will need to know your well pump’s power consumption. It should be stated on a plate on its motor housing. If it’s a buried submersible pump, check for this information on the control box instead.

If the power is stated in units of electric horsepower, then convert it into watts using the equivalence: 1 electric HP is approximately 745.7 watts.

To work out the current (amps) your well pump uses, apply the formula relating power, voltage, and current (P = IV) and the 80% rule:

Current the pump normally uses = Power (in watts) x 1.8 / Voltage (of your power supply)

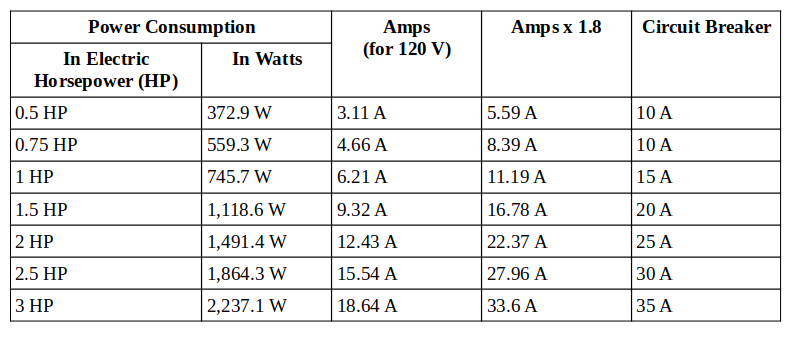

This will give the values shown in the table below. It assumes the voltage rating is 120 V.

Circuit breakers usually come in values a few amps apart, so you may need one that is a few amps higher than the value you calculated. It should be a little higher anyway, to consider the likely initial surge in current when the pump is turned on.

Special Considerations

In practice, you also need to consider three more important things in addition to those listed earlier. They are initial current surge, voltage drop, and distance:

- The initial current surge is usually high before stabilizing at a lower level, especially in a submersible pump. The circuit breaker must allow for the maximum surge. If the surge is high, use a factor of 2.5 instead of 1.8. You may find that you will need to use the next higher standard-size circuit breaker.

- Voltage drop – The voltage is usually tolerated within the range of ±5%. It will be higher if the distance is longer. Calculate the minimum and maximum values to ensure the circuit breaker covers them.

- Distance – The recommendations above are for when the pump is in sight of the circuit breaker enclosure. If it is more than 50 feet away, another means of disconnecting the pump must be arranged closer to the pump.

Wrapping Up

We considered what size circuit breaker should be used for a water pump. We assumed it was for a submersible pump in a 120 V system. Generally, a 1 HP pump would need a circuit breaker rated for 15 A, a 2 HP one would need a 25 A one, and a 3 HP one would need 35 A. However, the next higher one may be necessary if the initial current surge is expected to be very high to prevent frequent tripping. In short, the right size breaker is neither too low that it would often trip or catch fire nor too high that it fails to protect against high current and temperature in the pump’s motor itself.

Take a look at some of our related articles below.

- What size breaker does a dishwasher need

- What size breaker for AC unit

- What size wire for a 40 amp breaker

References

[1] David Herres. The homeowner’s DIY guide to electrical wiring. McGraw Hill. 2015.

[2] Gregory Fletcher. Residential construction academy: House wiring. Cengage Learning. 2015.

Video Reference

Pump Products