Knock Sensor Diagram

This guide will go through a knock sensor diagram and its working principles. Knock sensors play integral roles in vehicles, and you need to understand them well.

As an experienced mechanical engineer, I have handled numerous knock sensor projects and learned a few tips and tricks. A knock Sensor (Vibration Sensor) is a simple device that detects vibrations or shocks when knocked or tapped. It is an electronic switch that is normally turned on. It closes when it detects any shock or vibrations.

Quick Summary: A typical knock sensor consists of a conductive vibrating spring as the major sensing element, a resistor, and three pins. The Knock Sensor Module has 3 pins: GND, +5V, and S.

I will go through more below.

What Exactly is a Knock Sensor?

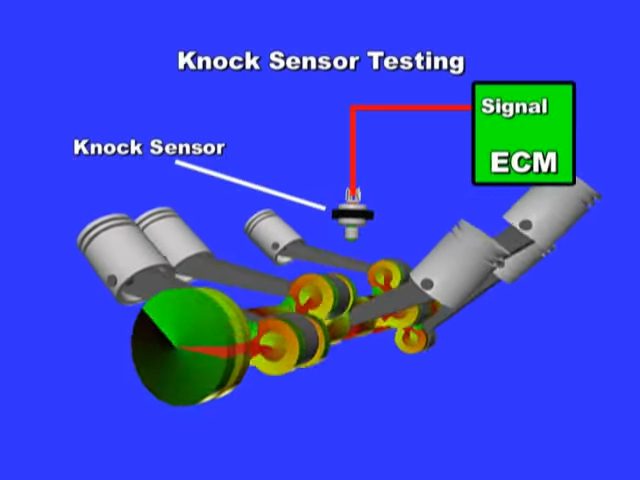

The knock sensor detects engine cylinder vibrations caused by knocking and sends an electric signal to the ECM (Engine control module).

When the ECM receives an electric signal, it retards the ignition timing or spark timing and prevents knocking within the engine.

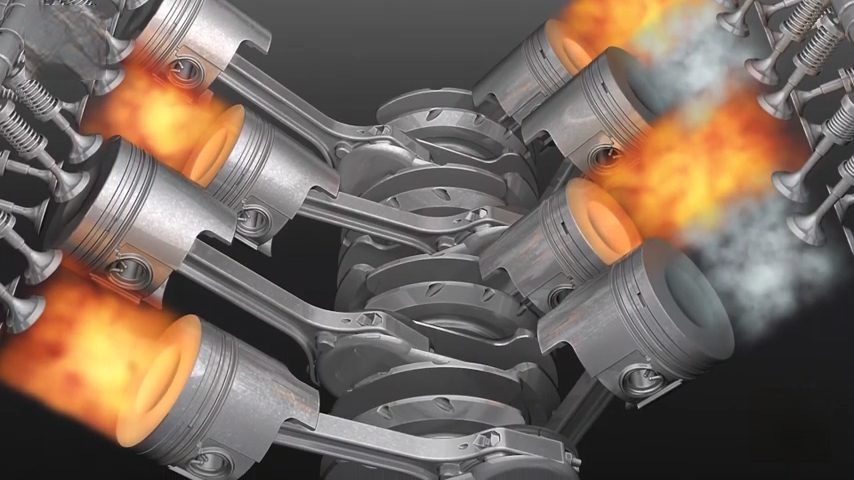

The voltage of the knock sensor’s electric signal is proportional to the knocking force. Thus, the knock sensor assists the engine by transmitting knocking signals to the ECM since knocking harms the engine. That’s because high temperature and vibrations produced during engine knocking damage the engine components.

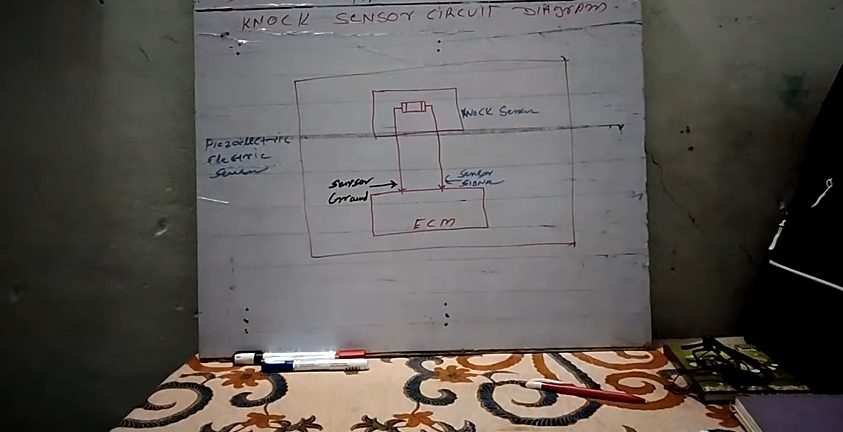

The Knock Sensor Diagram

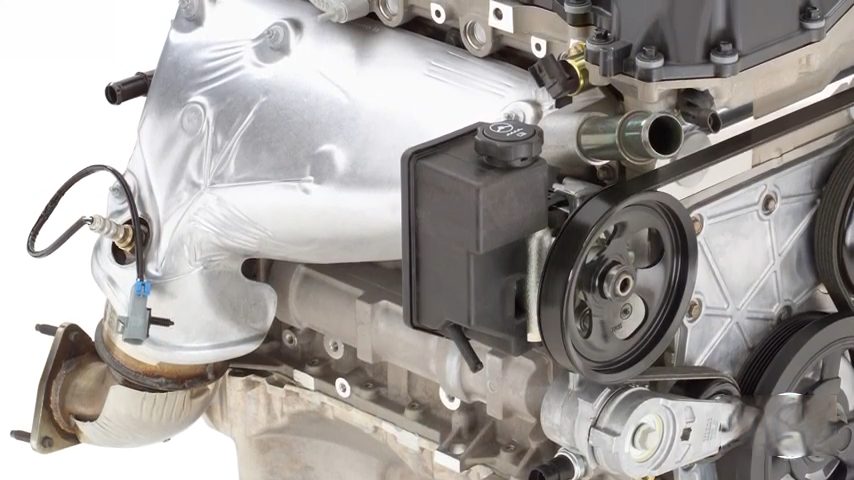

Location of the Knock Sensor: The knock sensor is attached to the engine block or the cylinder head.

The Working Principle of a Knock Sensor

The knock sensor is a piezoelectric type sensor that detects vibrations generated inside the engine due to knocking and sends electric signals to the ECM.

When the ECM receives voltage signals from the engine, it retards the ignition timing. As a result, ignition starts closer to TDC than before, reducing knocking inside the engine.

The knock sensor reduces the peak pressure and temperature inside the engine by delaying ignition timing, resulting in knocking stops.

The Roles of a Knock Sensor

- The roles of a knock sensor

- To cut down on power waste

- To increase fuel efficiency

- To boost the torque output

- To detect vibrations within the engine

Knock Sensor Components

The knock sensor consists of the following essential components (knock sensor construction):

Piezoelectric Element

The ceramic disc is the piezoelectric element. An electric charge accumulates when the piezoelectric element is subjected to pressure during engine vibration.

Contact Disks

The contact discs of a piezoelectric element are on both sides—the contact disks aid in transferring electric charge from a piezoelectric element to the terminals.

The Seismic Mass

The pressure on seismic material changes continuously and rhythmically due to the inertia of the seismic mass during engine vibration. As a result, the piezoelectric element detects the change in pressure, causing an electric charge accumulation in this element.

How Does a Knock Sensor Work?

The knock sensor is attached to the engine block with screws. When the knocking begins in the engine, high pressure and vibrations are produced. The electric charge accumulates inside the piezoelectric element due to the high vibrations.

A piezoelectric element has contact discs on both sides, so the electric charge produced inside the element flows from the contact discs to the terminals, which are then connected to the ECM (Engine control module).

The magnitude of the electric charge voltage is determined by the intensity of the vibrations produced by the knocking.

When the ECM receives an electric signal from the knock sensor, it delays ignition timing until the knocking ceases. As a result, the ignition occurs closer to TDC than before, and the knocking halts inside the engine.

When the knocking stops, the ECM returns to the previous ignition timing.

Application, Advantages, and Disadvantages of Knock Sensors

Application

To stop knocking, the knock sensor is used in many different types of two-wheeler and four-wheeler automobiles and construction machinery engines.

Advantages

The knock sensor has the following benefits

- Reduces the likelihood of knocking

- Improves horsepower and fuel economy

- Lower engine vibrations caused by engine knocking.

- Protects engine components from damage caused by engine knocking.

- Reduces the amount of unburned gas emitted.

- Enhances engine performance

Disadvantages

The knock sensor has the following disadvantages

- Noise generation during knocking reduces accuracy.

- Requires regular maintenance.

- High price.

- More complication.

- They wear out over time, necessitating a costly replacement.

Some Frequently Asked Questions — FAQs

What effect does the knock sensor have on the engine?

The knock sensor detects engine vibrations caused by knocking and sends an electric signal to the ECM. The ECM then retards the ignition timing to lower engine knocking.

Is a knock sensor necessary?

The knock sensor is essential in the IC engine for reducing engine knocking. As a result, engine performance improves.

What happens if a knock sensor fails?

When the knock sensor fails, the engine consumes more fuel, resulting in less acceleration and decreased engine power output.

What causes a knock sensor to malfunction?

The knock sensor fails primarily due to the breaking of the knock sensor wire and improper installation.

What are the symptoms of a faulty knock sensor?

A bad knock sensor causes an audible engine knocking sound from the engine, the Check engine light to light up, and the engine’s fuel consumption to rise, among other symptoms.

References

Website Resources:

- Accuracy. https://blog.paperspace.com/deep-learning-metrics-precision-recall-accuracy/

- Fuel consumption. https://www.sciencedirect.com/topics/earth-and-planetary-sciences/fuel-consumption

Video References:

NGKSparkPlugsUSA

sunder singh rathore