How to Wire Fuel Pump to Ignition Switch (Guide)

If you are a DIY mechanic nerd like me you get excited over the thought of upgrading your mechanical fuel pump to an electric fuel pump. Even though most won’t get it I can’t blame you for the excitement, we’re only human.

Without a doubt, electrical fuel pumps do a much better job than old-fashioned mechanical fuel pumps. From my personal experience, installing a new fuel pump is easy. But, the wiring part is a little tricky. Connecting the relay pins to the right place requires proper knowledge. So, today I’m hoping to familiarize you with how to wire the fuel pump to the ignition switch the right way.

In general, to wire an electric fuel pump, follow these steps.

- First, switch off the engine.

- Ground the negative post of the fuel pump and pin 85 of the relay.

- Connect pin 30 to the positive terminal of the battery.

- Connect pin 87 to the positive post of the fuel pump.

- Finally, connect pin 86 to the ignition switch.

That’s it. Now you know how to wire a car’s electric fuel pump.

Upgrade Options

Depending on your requirements, there are two different upgrade options. So, let’s check them out.

Option 1 – Keep Both Mechanical and Electrical Fuel Pumps

If you plan to keep the mechanical fuel pump as backup, place the electric pump close to the tank. This is not necessary since the electrical pumps are highly durable.

Option 2 – Remove the Mechanical Fuel Pump

Overall, this is the best option. Remove the mechanical pump and replace it with an electrical pump. Here are some simple steps to follow.

- Loosen the screws that are holding the mechanical pump and pull it out.

- Apply a block off plate gasket and sealer to the hole.

- Mount the electrical pump close to the fuel tank.

- Install a filter close to the electrical pump.

- Complete the wiring process.

Things You’ll Need

Here are some things you’ll need to carry out the electric fuel pump wiring process.

- Suitable electrical fuel pump (should match your car’s year, model, and make)

- Correct gauge wires (use at least 16 gauge)

- A block off plate gasket

- A sealer

- A mount for the car electric fuel pump

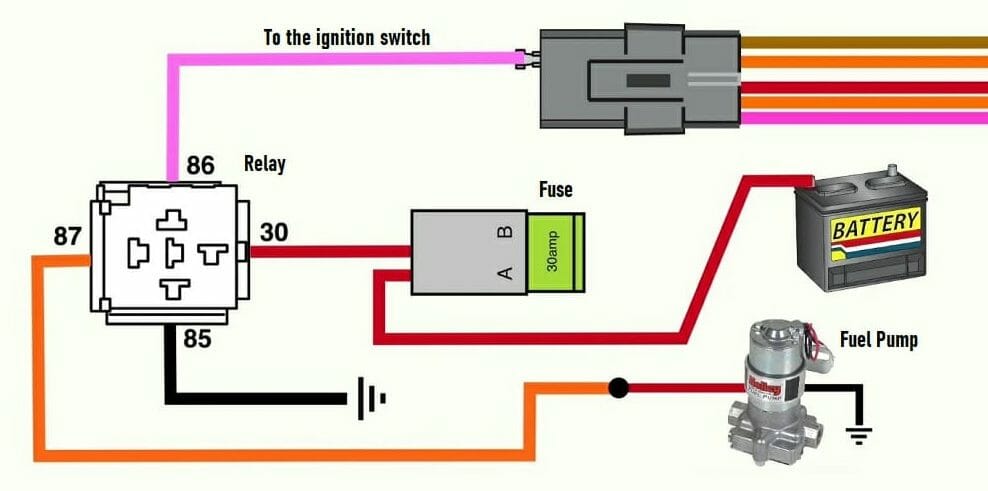

Wiring Diagram

As I mentioned, the most difficult part of an electrical pump installation is the wiring process. If you get it right, your car will have an excellent fuel pumping system that works flawlessly. Besides, considering the long life span of the electrical fuel pumps, you won’t have to replace them for a long time. With that in mind, here is the wiring diagram for the electrical fuel pump installation.

Tip: Use at least 16-gauge wire for this wiring process.

As you can see, all the items on the diagram are labeled. You should be able to understand the diagram without much issue if you familiar with electrical diagrams. However, I’m going to explain each item.

Electrical Fuel Pump

The electrical fuel pump has two posts; positive and negative. You must ground the negative post. Connect the negative post onto the car’s chassis. I’ll explain the connection of the positive post with the relay.

12V Battery and the Fuse

The positive terminal of the battery connects to the fuse.

Why Use Fuses

We use the fuse as protection against higher loads. The fuse has a small wire that melts quickly when the current is too high.

Relay

Most often, relays come with 5 pins. Each pin has its own duty, and we use numbers such as 85, 30, 87, 87A, and 86 to label them.

What is 85 on a Relay

In general, 85 is used as the ground connection, and 86 connects to the switchable power. 87 and 87A are connected to the electrical components that you want to control with the relay. Lastly, the 30 connects to the positive terminal of the battery.

So, for our electrical fuel pump,

- Ground the pin 85 using the car’s body or any other way.

- Connect the 87 to the positive post of the electrical pump.

- Connect the 30 to the fuse.

- Finally, connect the 86 to the ignition switch.

Keep in mind: We don’t need the 87A pin for this wiring process.

Common Rookie Mistakes You Should Avoid During the Installation

Even though electrical fuel pumps are highly reliable, a botched installation might break the fuel pump. So, avoid the below mistakes by any means necessary.

Installing The Fuel Pump Far from the Fuel Tank

This is a common mistake that most of us should avoid. Don’t install the pump far from the fuel tank. Always keep the fuel pump close to the tank for maximum performance.

Installing the Fuel Pump Close to a Heat Source

It is never a good idea to install the pump and fuel line close to a heat source. So, keep the pump and the line away from the heat sources such as exhaust. (1)

Not Having a Safety Switch

When you deal with a fuel pump having a safety switch is a must. Otherwise, the oil will start to leak everywhere during a fuel pump malfunction. To avoid all of this, install an oil pressure switch. (2)

Take a look at some of our related articles below.

- How to test fuel pump with multimeter

- How to test a 5-pin relay with a multimeter

- How to wire a fuel pump to a toggle switch

References

(1) heat source – https://www.sciencedirect.com/topics/physics-and-astronomy/heat-sources

(2) pressure switch – https://www.sciencedirect.com/topics/engineering/

pressure-switch

Video References

American Autowire

Airtex-ASC Performance Pumps

AnthonyJ350