What Gauge Wire from Battery to Starter (Size & Capabilities)

When connecting a battery to a starter, getting the gauge right is important because if the connection between them is not strong enough, you might experience some starting issues.

You might already know that thicker wire has lower resistance and can carry more current over longer distances. But the longer the wire, the more the voltage drops, so you’ll need thicker wire to account for this, too.

If this is confusing, I’ve made it easy with our handy guide to determining what gauge wire from the battery to the starter.

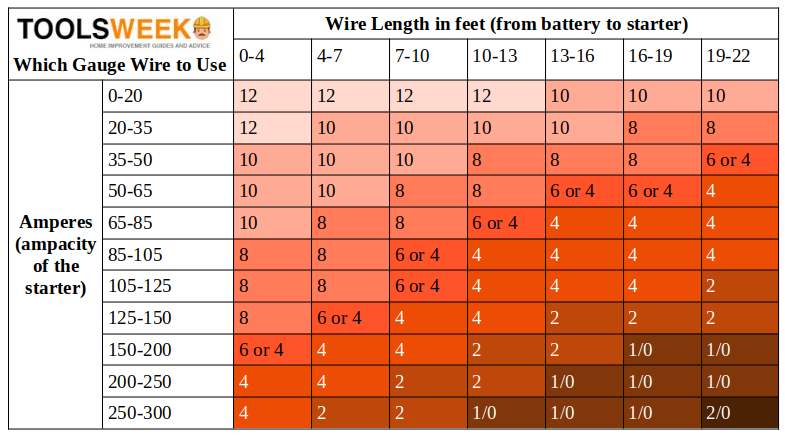

Usually, a two or 4-gauge wire is recommended from the battery to the starter (4-gauge for the positive wire and 2-gauge for the negative), which is thick due to the high ampacity. However, the gauge wire you should use depends on how much current your engine’s starter motor will draw and the cable length according to its distance from the battery. Use our chart below as a guide.

I will go into more detail below.

The Starter and its Ampacity

The battery and starter are two key components responsible for starting a vehicle.

The starter gets power from the battery to crank the engine and start the ignition. However, its ampacity varies because it depends on several factors.

We’re going to look at these factors so you can better understand what’s involved in determining the wire gauge.

Factors that Determine Battery Cable Size

Two key factors determine the right gauge cable to use for a car battery-to-starter connection:

- Ampacity (current carrying load)

- Voltage drop due to the distance between the battery and the starter

While a cable that is too thin will be unable to handle the high current and could get too hot and be a fire risk, one that is too thick will be an unnecessary expense and weight. So, we’re trying to find the most suitable gauge or cross-sectional area.

Ampacity

The larger the engine, the more amps the vehicle will need to start.

The starter’s ampacity will be somewhere between 50 and 1500 amps. Most passenger vehicles require between 125 and 225 amps. If it’s a 12-volt battery, the vehicle probably has a starter motor that draws between 150 and 200 amps. If it’s a large vehicle, it might even range between 300 and 500 amps.

Use our table below to figure out what the ampacity will likely be, or check the label on the starter for precise information.

| Engine or Vehicle Type | Typical Starter Draw (Ampacity) |

| Large trucks and other more powerful engine | 125-150 amps |

| V6 | 175 amps |

| V8 | 225 amps |

| SUV | 200-300 amps |

| Large trucks and another more powerful engine | Up to 1500 amps or more (max ~2000 amps) |

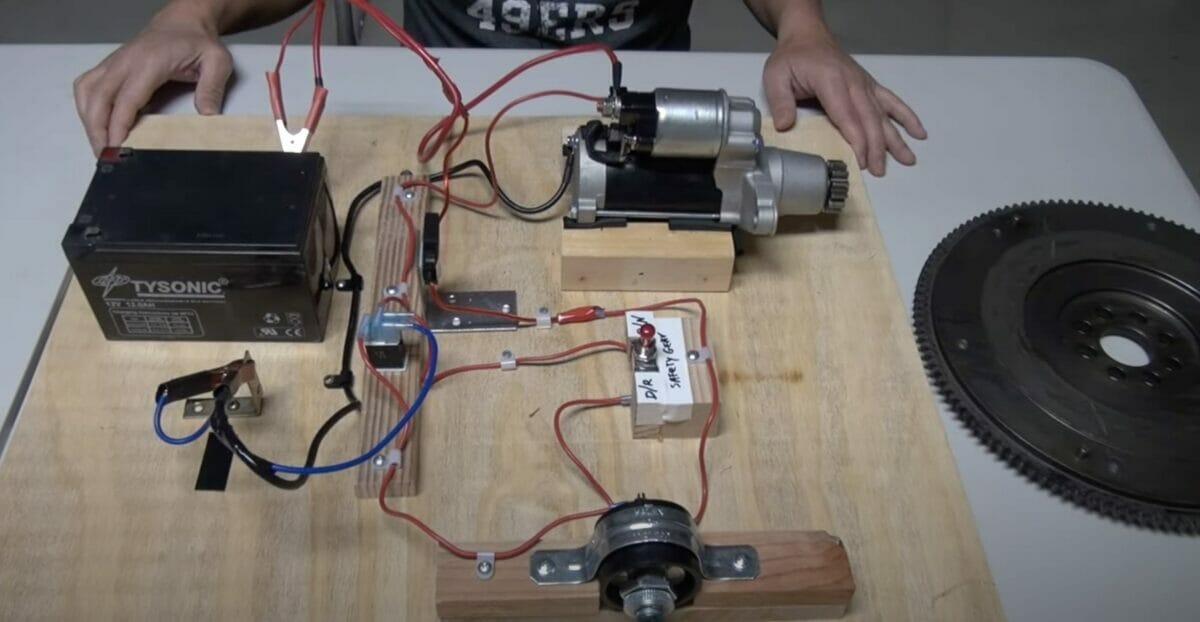

Is the starter outside or inside a vehicle?

Whether a starter is spinning freely or cranking an engine makes a difference. If you’re only testing a starter on your workbench, it might draw around 80 or 90 amps, but the same starter may draw between 250 and 350 amps when starting an engine.

Other factors that determine the actual amps passing through the cable include the condition of the battery and starter, corrosion on the terminals, the ambient temperature, and the engine oil’s thickness (viscosity).

Voltage Drop or Distance

The distance between the battery and the starter determines the length of wire you need because voltage drop is another important factor.

Generally, the longer the distance, the higher the voltage drop, requiring thicker wire.

Also, most vehicle manufacturers specify a tolerable voltage drop of up to 0.5 volts, which applies to 12-volt systems. So it should only be a concern if it’s more than this. In a 24-volt system, it should not exceed 1 volt. Note that this is the total loss on both the positive and negative wires.

Besides cable length, the voltage drop can also be affected by loose connections, corrosion, and improperly crimped connectors.

So what should you do if the voltage drop is too high?

There’s too much resistance if the voltage drop is too high (more than 0.5 volts in a 12-volt system). The voltage may be insufficient to start the car, so you’ll need a thicker (i.e., lower gauge) wire to minimize the distance between your battery and the starter.

Battery Cables

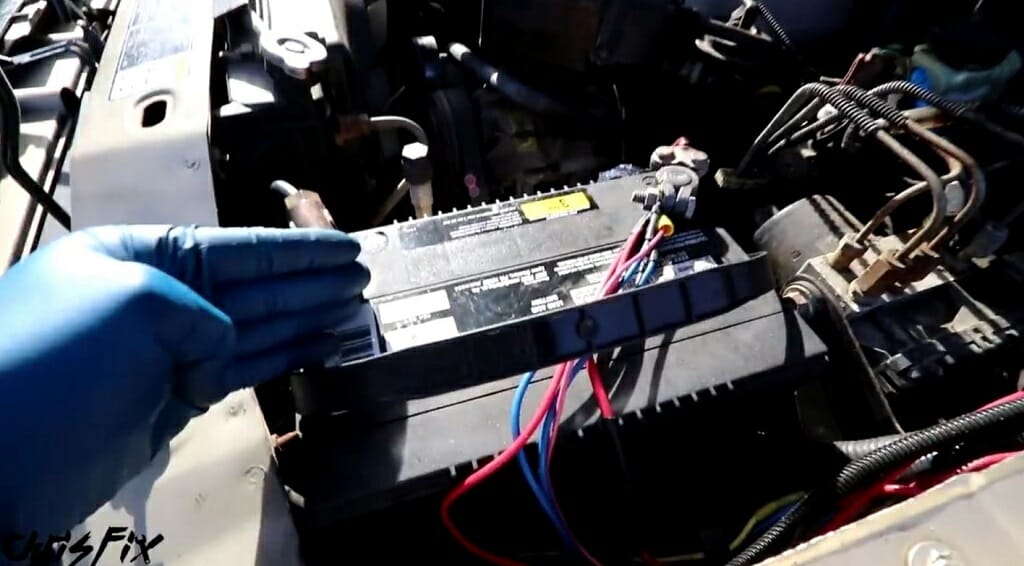

Battery cables are typically high-current carrying conductors that connect the battery to the vehicle’s electrical system, including the starter.

They are thick due to the high current they have to tolerate. A 4-gauge cable is a common size (as in the picture below). The conductor inside is typically copper due to its low resistivity or high conductivity.

Exact Gauge Wire to Use

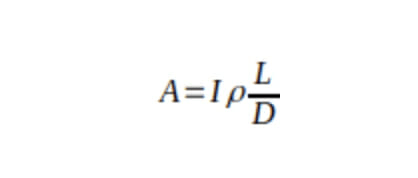

Knowing exactly what gauge wire you need from the battery to the starter requires some calculations to determine the wire’s cross-sectional area.

The formula to work this out is

Where:

- A is the cross-sectional area in square meters;

- I am the maximum current through the wire in amps;

- ρ is the conductor’s resistivity;

- L is the wire’s length in meters;

- and D is the maximum allowable voltage drop in volts.

Then, convert this and find the equivalent in the AWG (American Wire Gauge) system.

I made it easy for you by giving you the chart at the top, but if you prefer to do the calculation, use these values:

I: The current draw depends on the engine size, starter motor’s condition, oil viscosity, and temperature. A typical 4-cylinder engine draws 125-150 amps.

For other engine types, see the table I gave earlier or the vehicle owner’s manual for the exact amperage.

ρ: A typical PVC-coated copper cable used in motor vehicles has a resistivity of about 1.7 x 10-8 Ωm.

L: This is the cable’s length from the battery to the starter in meters.

D: The typical voltage drop for a 12V starter circuit (for maximum load at 20°C) is 0.5 volts. [Denton, 2007, p. 84]

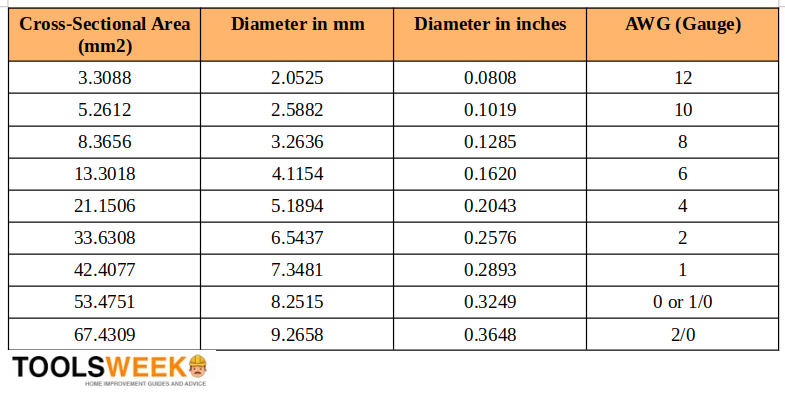

Wire Gauge Sizes

When calculating the cross-sectional area, you will obtain a square-meter metric value using the above formula.

Convert this to the area in square millimeters:

area in meters squared x 106 (or 1,000,000) = area in millimeters squared

Then, refer to the table below to find the equivalent in the AWG system (within the range of 12 to 2/0).

Other Things to Be Careful About

Besides considering the battery cable’s gauge, there are a few more things to confirm when connecting the battery to the starter or other electrical components.

In particular:

- Ensure that the battery is held down securely to tolerate the vibrations of a running engine.

- Ensure all connections are tight and clean to prevent arcing, corrosion, and high-voltage resistance.

- Use the battery’s heat shield, if supplied, to protect the battery from high temperatures.

- Check the battery periodically to ensure its electrolyte level is sufficient.

A Vehicle’s Starting System

The connection between the battery and the starter is not the only part of the circuit that the vehicle’s starting system (see the illustration below) relies on.

Other important parts are the ignition switch, starter solenoid or relay, starter drive, and starter safety switch.

So, to ensure the starting system functions optimally, you must also ensure these other parts operate normally.

To put it another way, if you experience a starting problem and the cable from the battery to the starter is secure, undamaged, not overheated, and of the right gauge, you should check the other parts of the starting system.

References

Website Resources:

- 4-gauge battery cable. https://www.fischermotorsports.com/fm-store/electrical-systems/mil-spec-wire/custom-cables/4-awg-battery-cables/

Books:

- Barry Hollembeak. Automotive electricity and electronics. Today’s technician: classroom manual. 7th edition. Cengage Learning. 2019

- Tom Denton. Automobile electrical and electronic systems. Taylor & Francis. 2007

Video References:

Wiring Products

ChrisFix

Howcast