What Does the Battery Control Module Do?

The Battery Control Module (BCM) stabilizes a vehicle’s electrical system.

The BCM monitors the vehicle battery’s state of charge (SOC), indicating the energy available. The BCM specifies the required charging current to charge the battery using this information. It maintains the charge level at 80% by reducing the charging current when the battery overheats. A BCM can also be programmed to simplify the wiring harness, combine the monitoring functions in a single control unit, and record data.

It is also called a Battery Management System (BMS).

Main Functions of a BCM

A Battery Control Module (BCM) typically manages the following battery aspects:

- Charge level – It maintains the charge level by controlling the charging current and, when necessary, allowing discharging and preventing overcharging.

- Temperature – It monitors the battery’s temperature to equalize the charge rate and prevent overheating.

- Voltage monitors the battery’s voltage level to equalize the charge rate.

- Resistance – It monitors the insulation resistance.

The overall goals for which they are used are to prevent overcharging, overheating, maximize the battery’s life, and ensure optimal performance. In short, they help to prolong battery lifetime by preventing premature capacity loss.

Wright & Duffy (2019, p.1588) describe what a BCM does:

“A battery control module measures battery temperature and voltage to equalize the battery charge rate. Lower-voltage batteries receive more charging voltage, and less-resistive batteries capable of faster charging receive slightly lower current.”

More advanced models are also capable of:

- Battery cooling (advanced thermal management)

- Battery SOC reporting

- Fault detection

- Precisely controlling individual cells to maintain cell balance (integrated function)

- Transmitting the information about the battery to the vehicle’s central control system wirelessly (communication function)

- Capturing extra energy during regenerative braking to help recharge the battery (regenerative function)

- Providing historical battery data and making estimates of future states (battery state estimation)

- Switch management (in the case of battery packs)

Some versions are specially made for higher-voltage batteries than the standard 12-volt ones used in hybrid and electric vehicles.

Types of BCM

Although different types of BCM have a similar main function relating to managing the battery, some types are specially made for specific functions.

| Type of BCM | Passive (Simple) Function |

| Passive (simple) | It monitors the battery’s voltage and temperature and disconnects the battery in the event of an overcharge or overheating. |

| Active (advanced) | It actively manages the battery, using algorithms to control charging and discharging to maximize battery life and performance. |

| Integrated | It is integrated into the battery pack to precisely monitor and control individual battery cells or modules. |

| Distributed | It is integrated into the battery pack to monitor and control individual battery cells or modules precisely. |

| Wireless | It uses wireless communication to transmit battery information to the vehicle’s central control system. |

| Dual-Battery | It manages high-voltage batteries used in hybrid and electric vehicles, ensuring the safety and optimal performance of the battery system. |

| Regenerative | It manages the battery’s charging during regenerative braking, capturing energy that would otherwise be lost and using it to recharge the battery. |

| High Voltage | It manages high-voltage batteries used in hybrid and electric vehicles, ensuring the safety and optimal performance of the battery system. |

BCM Architecture

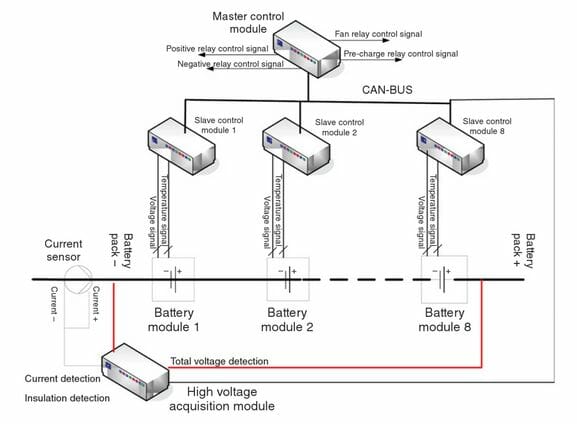

A BCMs architecture can be divided into centralized and distributed parts. [Jiang & Zhang, 2015]

The centralized architecture’s functions of monitoring the current (charge), temperature, voltage, resistance, etc., are roles. It relies on concentrated sample points obtained from multiple Battery Measurement Units (BMUs) as part of the distributed architecture.

The BCM processes all the battery parameters from each BMU and the SOC, SOE, SOH, and SOF. In some newer BCM models, the centralized functions are handled by a master control module, whereas agent modules handle more specific functions or individual batteries in a battery pack.

Here’s an example of a distributed BCM architecture:

BCM Control

The BCM controls the battery’s charging and discharging by making continuous calculations and following algorithms.

The calculations involve two key metrics to indicate battery performance: SOC and SOH.

SOC (State of Charge)

SOC, measured in percentage, means the initial State of Charge of the battery.

It indicates the battery’s capacity and shows the amount of charge remaining.

It is calculated as remaining capacity / rated capacity x 100%

Besides capacity, temperature, and voltage, the SOC value takes the following additional parameters into account:

- Battery’s chemistry

- Charging/discharging rate

- Current

- Impedance

SOH (State of Health)

SOH means the State of Health.

All batteries degrade over time, so the SOH gradually declines below the initial level. SOH data can give an early warning sign of deterioration and impending failure.

It is calculated as maximum charge / rated capacity x 100%

Besides capacity, temperature, and voltage, the SOH value takes the following additional parameters into account:

- Age

- Cycle life (charge/discharge cycles)

- Energy throughput

- Internal resistance

- Self-discharge rate

Advanced BCM Functions

Here, I’ve focused on two advanced BCM functions: recording and thermal management.

Recording Function

Some BCMs can record battery-related data to provide historical information.

They can usually record data for up to 100 driving and stationary cycles. Note that the charging rate is positive in a driving cycle because it indicates a charging state, whereas it is negative in a stationary cycle. After all, the battery is gradually drained of power.

Thermal Management

BCMs capable of advanced thermal management help to keep the battery cool (or warm) while driving to ensure it performs optimally.

This is in addition to the role of measuring the monitoring the temperature. Advanced thermal management involves:

- Applying heat dissipation methods when the temperature is too high.

- Rapid heating when the battery’s temperature is too low.

- Equalization of battery temperature throughout the battery pack.

Air cooling is a common cooling method, as it’s easy to implement, but liquid cooling is also being researched as it offers a better cooling effect. [Xiong & Shen, 2019, p. 237]

BCM Malfunctioning Symptoms

Here are some symptoms to look for that indicate the BCM may be malfunctioning, i.e., not doing what it is supposed to do:

- The dash-mounted warning light illuminates.

- The hybrid battery fails to charge or remains charged.

You should fix a malfunctioning BCM soon because it can negatively affect the battery’s charge, making it drain quickly. You won’t get the benefits of a working BCM until you do that.

Examples of BCMs

BCM-0000-B

The BCM-0000-B monitors the entire control panel’s power supply comprising up to 4 batteries, based on temperature and time. It has three special functions:

- It can activate the LED test if you push the key.

- It starts charging if the voltage is between 18 and 21 volts and there is a mains power supply.

- It deactivates output if an error occurs.

The TSP-BCMU360 Series

The TSP-BCMU360 is a universal BCM for uninterruptible 24- or 48-VDC bus voltage.

It offers redundant inputs for two independent sources; battery protection for short circuits, over-voltage deep discharge, reverse connection; alarm; and temperature-controlled charging.

FAQs

Where is the BCM located?

The BCM’s location depends on the type of battery in the vehicle.

How many BCMs are there in my vehicle?

Electric and hybrid vehicles may have more than one BCM. Otherwise, there is usually only one, although it may be centralized or distributed.

Do I have a centralized or distributed BCM?

Vehicles with more than one battery, such as large trucks, may have multiple BCMs unless combined. So, cars with battery packs, i.e., multiple batteries, usually have a distributed BCM architecture, where a separate BMU monitors each battery.

References

PSM24-BCM360S. https://www.automationdirect.com/adc/shopping/catalog/power_products_(electrical)/dc_power_supplies/specialty_modules/psm24-bcm360s

CM-0000-B Battery controller module. https://resources-boschsecurity-cdn.azureedge.net/public/documents/BCM_0000_B_Battery_c_Data_sheet_enUS_91832213131.pdf.

Gus Wright & Owen C. Duffy. Fundamentals of medium/heavy duty commercial vehicle systems. Jones & Bartlett Learning LLC. 2019

Jiuchun Jiang & Caiping Zhang. Fundamentals and applications of lithium-ion batteries in electric drive vehicles. Wiley. 2015

Rui Xiong & Weixiang Shen. Advanced battery management technologies for electric vehicles. Wiley. 2019

TSP-BCMU360 series. https://www.tracopower.com/products/tsp-bcmu.pdf